We increase your production efficiency

Accurate understanding of the problem

gives us the opportunity to improve

the production, process and make it

more profitable

Problem

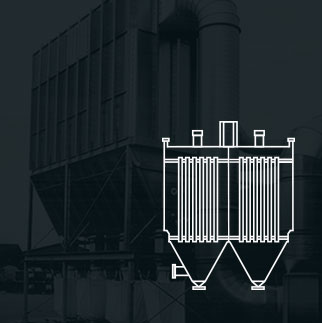

Nonffective dust extraction

Solution

Exploitation of multicyclones as a pre-treatment devices which will relieve the load in the form of large dust before the subsequent pieces of equipment. The cyclones are designed to clean the large gases flows with a high purification efficiency and resistant to thermal and abrasive wear.

Upgrade

Problem

Noneffective hot gasesdust recovery

Solution

The Venturi scrubbers utilization allows to execute of highly efficient dust/liquid particles capture with dimension of less than 1 µm from the hot gases stream, cooling it simultaneously. At the same time, in order to simultaneously absorb, it is possible to retrofit Venturi scrubber with the efficient centrifugal, rotary and other mass-transfer stages.

Upgrade

Problem

Low efficiency of purification

Frequent downtime due to the fact of the clear section clogging

Spending on electricity because of unreasonably high hydraulic resistance and density of irrigation

Solution

We offer highly efficient heat and mass transfer scrubbers, the operating principle of which is based on the creation of an active surface of phases contact, with the turbulent regime. Depending on requirements and the purified gas composition the company offers a variety of unique design centrifugal, rotary, dynamic, and Packed scrubbers.

Upgrade

Problem

Disposal and purification of gases from volatile organic compounds

Solution

We suggest to use thermal and catalytic installations for the high-calorie gas emissions, including at the same time, organic compounds, disposal. This allows in addition to the effective cleaning get the heat in the form of steam or hot water, and the electrical power.

Upgrade

Problem

Сapture of toxic pollutants and solvents

Solution

If there is necessity in solvents trapping with the purpose of their regeneration or toxic pollutants low concentrations sequestration we suggest adsorbers application, which equipped with a charge (bad, adsorbents), specially selected depending on the absorption properties of the adsorbates.

Upgrade

Problem

Сhanges the bags

Low productivity and efficiency by the large overall dimensions of the bag filters

Solution

Cartridge filters provide cleaning of all dustup to 0.1 microns from wet, acidic gases, achieving a residual dust content of 0.2 mg/m3. Service life of filter elements for more than 10 years.

Upgrade

Problem

No quality classification when the hyperfine separation

Performance degradation due to the increasing of the circulating load, the material over crushing

Solution

Engineering of the thin classification units – AKA-SPIDER pump-hydrocyclone units operating in fully automatic mode.

Upgrade

Problem

Is there a high degree of wear of the hydrocyclone parts which are in contact with the pulp

Solution

Nozzles, spigots and modules of hydrocyclones AKA-VORTEX are made from high strength materials such as: polyurethane, oxide ceramics, injection molded polymers, chromium steel.

Upgrade

Problem

The high level of the capital and operating costs for compensation of water losses

Problems of internal loop water circulation in the production

The large area of tailing facilities

Solution

Internal water circulation system using a high-performance thickener AKA-SET in tandem with the AKA VORTEX thickening hydrocyclones.

- - Automated systems of coagulants dosing.

- - Analysis of the condensed product density, the purity of the plum.

- - Control and calibration in real-time mode.

Upgrade

Problem

The low disintegration and flushing from the sludgeand clays

Solution

Intense disintegration and flushing from the sludge and clays, carried out in a AKA-DRUM scrubber-butare with capacity up to 350 t/h Screw separators AKA-SPIN allow effectively to enrich the products of preparatory operations. High quality concentrate is a guarantee of greater selectivity in the processes of metallurgy.

Upgrade

Problem

Poor performance of filter separation

High residual moisture of the cake

Insufficient purity of the filtrate

Solution

Theextensive experience of our company in the modernization of existing filtration equipment allows us to offer various technical solutions to improve the efficiency of the filtration stage while reducing operating costs.

Upgrade

Problem

Poor filtration compartment performance

High residual moisture in the cake

The filtrate is not clean enough

Process disturbances and high consumption of filter cloths associated with product crystallization

Solution

The extensive experience of our company in the modernization of existing filtration equipment allows us to offer various technological solutions to improve the efficiency of the filtration stage and reduce operating costs.

Upgrade

Problem

High energy costs and low energy efficiency

Formation of deposits in the heating chambers leading to process disruption

Solution

Application of multi-shell evaporators based on modern evaporators with thermal and mechanical vapor recompression systems. An individual approach to design based on the overall thermal balance of the entire system as a whole.

Upgrade

Problem

Difficulties in operation and control of technological modes

Unsatisfactory crystal quality and size

A lot of waste and loss of the target product

Frequent downtime due to the need to flush equipment

Solution

The selection of evaporative or cooling crystallizers of the optimal design, including multi-stage circuits with intermediate filtration and elutriation chambers, are reliable and proven solutions for obtaining high-purity crystals.

Upgrade

Problem

Unsatisfactory final product moisture

High product content in the centrate

Difficulty due to sticking or abrasive action of particles

Ineffective flushing with the correct solvent

Solution

The use of modern highly efficient centrifuges of various designs, as well as the possibility of manufacturing filter baskets that meet the specific requirements of the process in question, will allow you to achieve the required product quality in all situations

Upgrade

Problem

High humidity in the final product

Inhomogeneous drying conditions, product degradation or damage, clumping or sticking

Violation of temperature condition

Low energy efficiency

Waste product loss

Solution

The choice of the correct design type and individual calculation of all parameters of the drying mode, including the optimization of heat and material flows - the specialists of out company are ready to offer you comprehensive solutions in the field of drying and conditioning bulk materials of various types.

Upgrade

Problem

High temperature of the product before packaging, which degrades the quality of the product during storage

High energy consumption and difficulties in organizing the process of cooling the product by convective methods

Solution

Plate heat exchangers for bulk solids are a simple, reliable and effective solution for cooling your product before storage, filling or other processing stages. Significant reduction in energy costs and ease of use compared to traditional convective air cooling systems

Upgrade

Problem

Various difficulties during transportation leading to disruptions in the operation of technological lines

High wear and clogging of mechanical parts due to low design efficiency

Solution

Gambarotta's high-performance elevators with wear-resistant GUFA teeth and specially shaped buckets with wear-resistant pads are a reliable solution to keep your production lines running smoothly.

Upgrade

Problem

High humidity of the end product

Heterogeneous conditions of drying, decomposition of the product, the formation of lumps and sticking

Violation of temperature

Low energy efficiency

Product waste with waste gases

Solution

Upgrade

Problem

Not enough gas cleaning level or product loss with waste gases

High energy costs due to unreasonably high hydraulic resistance of the system

Сheap workmanship, foulness in high temperature conditions

Increased operating costs?

Solution

Upgrade

Problem

Solution

Upgrade

Problem

Solution

The process structuring, engineering with the use of high-performance thickeners AKA-SET in tandem with hydrocyclones-thickening AKA-VORTEX.

-

Automated coagulant dosing systems.

-

Analysis of the density of the condensed product, the purity of the drain.

-

On-line monitoring and calibration (in real-time mode).

-

A constant degree of the product condensation

- The use of special materials and linings

Upgrade

Problem

Low filtration performance

High residual moisture cake

Insufficient filtrate purity

Solution

Upgrade

Problem

Insufficient quality of filtration of carbonated or evaporated syrup

Solution

Highly effective candle or leaf self-cleaning pressure filters are a fully automated and reliable solution to reduce the turbidity of the solution and remove the smallest particles.

Upgrade

Problem

Low filtering performance

High residual moisture of cake and large losses of the target product

Not sufficient purity of the filtrate

Solution

Replacing existing vacuum filters with a special design filter press. Full automation and reliable process control.

Chamber and membrane filter plates produced Lenser Filtration GmbH - a high level of quality, individual selection of materials and their combinations.

Possibility of modernization of existing filtering equipment in order to significantly improve the quality of washing the precipitate and reduce its residual moisture.

Upgrade

Problem

High steam consumption and low energy efficiency

Scale and process disturbance

Solution

The use of multiple effect evaporators based on film technology with thermal and mechanical vapor recompression systems.

Upgrade

Problem

Insufficient crystal quality

Low performance or high power consumption

Solution

The use of cascade massecuite boiling systems based on vacuum-evaporating and cooling crystallizers - precise control of temperature and time conditions, as well as reducing the mechanical effect on crystals.

Modernization of existing equipment by replacing tubular heating chambers with “honeycomb” type chambers - increasing the heat transfer area up to 25% with the same equipment dimensions, as well as installing circulation mixers.

Upgrade

Problem

High moisture or increased crystal content in the centrate Inadequate washing quality

Solution

The use of modern high-performance filtering centrifuges of continuous and periodic action to achieve unique separation parameters.

Upgrade

Problem

High humidity of the final product

Non-uniform drying conditions, lumping and sticking

Abrasion and destruction of crystals with the formation of a large amount of dust

Violation of temperature conditions. Low energy efficiency

Solution

The use of modern drum dryers or static and vibrational fluidized bed dryers - the creation of soft and uniform conditions inside the apparatus to preserve consumer properties and achieve high product quality. A unique vibratory drive system for fluidized bed dryers with the ability to automatically control product residence time and fluidized bed height without the need to stop equipment.

The ability to organize dust removal of the product by removing small particles from the layer with their capture in the air filtration system and then returning to the process.

Upgrade

Problem

High temperature of the product after drying, worsening the quality of the goods during storage

Solution

Plate heat exchangers for bulk solids are a simple, reliable and effective solution for cooling sugar before being stored and packed. Significant reduction in operating costs compared to traditional convective air cooling systems.

Upgrade

Problem

- High moisture content in product

- High solid content in centrate

- Difficulties due to sticking or abrasive particles

- Difficulties with cake washing

Solution

The use of modern high-performance centrifuges specially designed for working with organic and polymer products, as well as the possibility of manufacturing filter baskets that meet the specific requirements of the process, will achieve the required product quality in any situation.

Upgrade

Problem

- High humidity of the final product

- Non-uniform drying conditions, decomposition of the product, lumping and sticking

- Violation of temperature conditions

- Low energy efficiency

- Loss of product with flue gas

Solution

Choosing the right design and individual calculation of all process parameters of the drying mode, including optimization of heat and material flows, our specialists are ready to offer you comprehensive solutions in the field of drying and conditioning of bulk materials of various types.

Upgrade

Problem

Difficulties with cleaning and disposal of scrubber fluid

Solution

The use of highly efficient liquid / liquid and solid / liquid separation systems, as well as various types of filters, making it possible to remove contaminants and return the purified liquid to the process, reducing costs and increasing the environmental friendliness of your production.

Upgrade

Problem

- Sticking to internal devices of resins, fatty acids and other sticky particles

- High pressure drop when cleaning from micron and submicron aerosols

Solution

The use of special rotary scrubber and other types of scrubbers, completely protected from sticking and any inlays and achieving the required gas cleaning efficiency without increasing of pressure drop

Upgrade

Problem

- Sticking on poppet valves, leakages of waste gas, drop of the efficiency

- RTO system corrosion

- Loss of efficiency, frequent shutdowns due to failure of the valve sealing device

Solution

- Usage of the of horizontal poppet valves, which does not lead to the accumulation of particles on the plate

- Usage of the special anti-acid coatings inside the chambers

- Preheating of the waste gas with its own heat of purified gas (recirculation) in order to prevent condensation of acid aerosols inside the RTO

- Usage of the of highly efficient scrubbers that guarantee the absence of particles and drip moisture (see our scrubbers)

- Usage of the of special self-cleaning metal-metal valves that do not require seals and gaskets

Upgrade

Problem

- Difficulties in the classification of bulk solids

- Need for additional grinding or destruction of lumps and agglomerates

- Various difficulties during transportation, leading to disruptions in the operation of technological lines

Solution

High-precision classifiers, elevators and conveyors of various types, coolers, mills and dispersers for wet and dry grinding - all that is necessary to ensure reliable and uninterrupted operation of production lines.

Upgrade

Problem

- Not flexible technology

- Unstable product quality

- Low degree of polymerization

- High energy consumption and insufficient environmental friendliness?

Solution

The development of individual design solutions for the modernization of polymerization plants of various products - modern, highly efficient technologies ranging from reactor systems to optimized distillation processes and vacuum systems for efficient process control.

Upgrade

profit after modernisation

Apply technological solutions to the scheme to measure the result

We are financially responsible

for the result

Offered You technological solutions carefully checked by our specialists and scientific staff of our partners - design institutes and manufacturers of the equipment.

The technological process is simulated on the computer, and industrial tests at the plant of the customer carried out as well. In the case of a new designed plant, we arrange visits to factories have already implemented this technology.

All this gives us the ability to guarantee the parameters of the technological process. Our company financially responds for its achievement by the contract.

We protect

the environment

Engineering protection of environment

The "ChemInS" company's team successfully creates and implements system for the protection of the environment from the negative impacts of industrial enterprises.

Our solutions provide guaranteed environmentally safe co-existence of the technosphere into the biosphere. "Chemins" company able to help fabricators with the requirements compliance to environmental legislation, establish and operate environmentally sound and resource-efficient gas cleaning system and wastewater treatment.

profit before modernisation

8 380 000

- Gas purification

- Mining

- Chemistry

- Metallurgy

- Sugar production

- Petrochemical industry

Services

R&D and research work

Design

Equipment modernization

Installation and commissioning works

Service maintenance

Reverse engineering

1.

R&D and research work

Conduct of scientific research to control the correct selection of equipment. Including laboratory and industrial tests.

2.

Design

ChemInS, LLC performs complex engineering in the field of industrial enterprises aspiration, separation and filtration of gas and liquid environments.

3.

Equipment modernization

Modernization of obsolete (out-dated) equipment or processing chain complex reconstruction. As a result, efficiency improving, maintenance costs reducing.

4.

Installation and commissioning works

Installation or installation supervision of the supplied equipment. Process starting-up and adjusting to project characteristics.

5.

Service maintenance

Maintenance of the equipment supplied on a contract basis. To prevent unexpected failure, prolongs the service lifetime.

6.

Reverse engineering

Reverse engineering (reverse engineering or reverse design) is the process of developing design documentation and/or a 3D model of a product based on a finished product sample.

Our company is a team of experienced professionals ready to offer comprehensive solutions for your production.

Our purpose

Our solutions

Advantages

Rapid assessment

Our experts will assess the effectiveness of technological circuit effectiveness on site. Upon the results will be given a report and prepare a feasibility study.

We do not sell an equipment as it is, we are looking for capability to increase the efficiency of your production.

Production upgrade

We offer not only new equipment but also the modernization of existing one.

In the framework of the mineral processing "ChemInS" is one of the few companies willing to realize the modernization of the classification and dehydration node with a guaranteed increase of efficiency from the existing one.

Individual approach

We offer solutions tailored to specific branches of industry.

The ability to test

Laboratory and industrial tests on the basis of the accuracy allow to simulate a various technological processes and ensure the correct equipment selection.

Reliable results

Close cooperation with leading scientific-research and design institutes guarantees the reliability of the proposed solutions.

Rapid return on investment

Our technology ensures minimum operating costs and high productivity, thereby reducing return on your investment.

Integrated solutions

Selection, design and various types of equipment supply of one technological chain in the complex.

Maintenance

Own service team.

Equipment

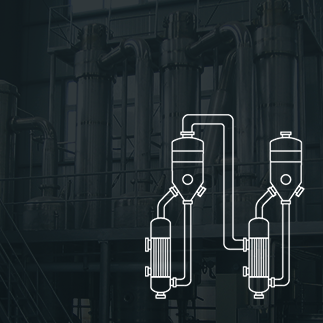

Evaporation Units

Evaporators

- Forced circulation

- Natural circulation evaporator

- Forced circulation evaporator

- Rising film evaporator

- Falling film evaporator

- Mechanical vapor recompression

Crystallizers

- Forced circulation crystallizer

- Evaporator/crystallizers with internal circulation pipe

- Fluidized bed evaporator/crystallizers

- Indirect forced circulation evaporator/crystallizer

- Thin film evaporators

- Multiple-effect installations and complex production lines

- Cooling crystallizers

-

Block modular Installations

Industrial waste disposal plants

- Waste gas incinerator

- Waste Liquid Incinerator

- System of thermal oxidation of solid waste

- Pyrolytic Controlled Gas Incinerator

Packing and transportation equipment

- Apron feeders

- Surface feeders

- Bucket elevators

- Bucket elevator with EVN rubber conveyor belt

Up