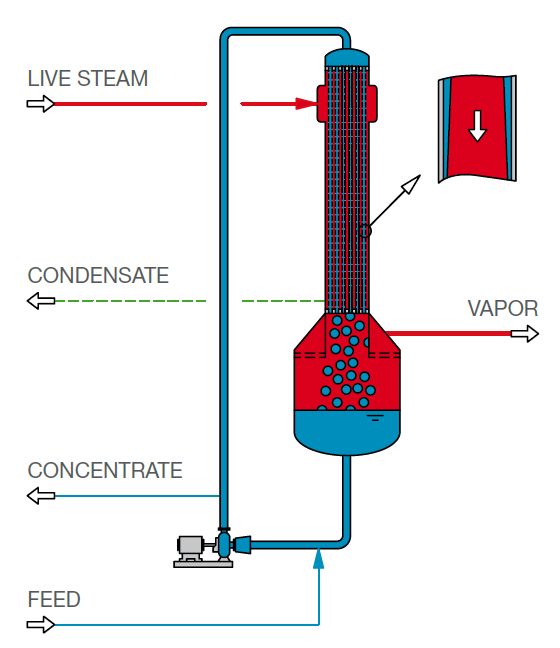

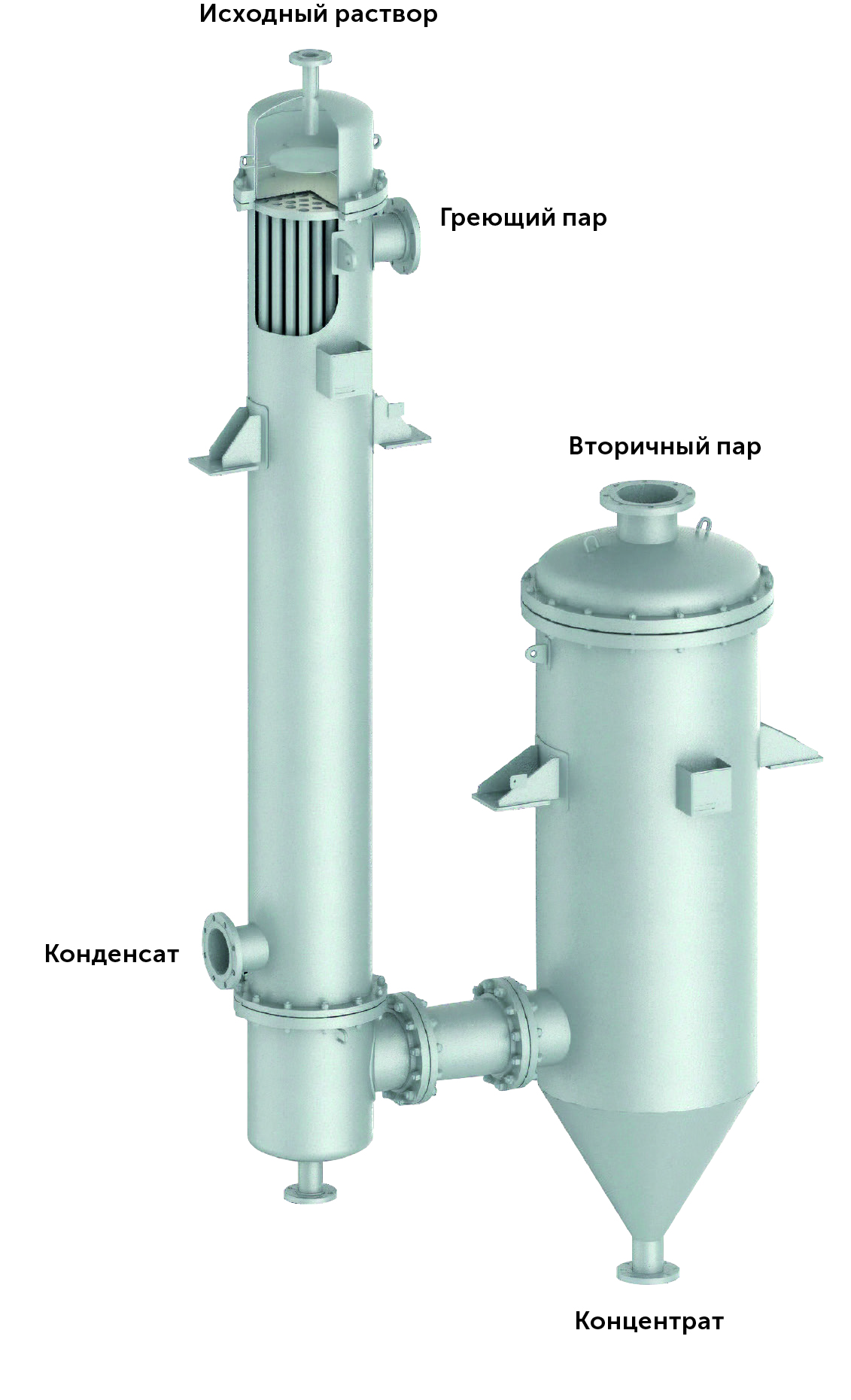

Falling film evaporator

The initial solution is fed to the upper part of the heating chamber and distributed through the pipes using a special device, forming a thin film that evenly moistens their surface.

Questionnaire

download

Advantages:

Compact design that allows the use of devices with a high heat exchange surface

Short contact time at low temperature differences-ideal for heat-sensitive products

Able to work with high-viscosity solutions

Low hydraulic resistance, the possibility of creating a deep vacuum and excellent heat transfer conditions are one of the most energy-efficient solutions.

Scope of application:

Most salt and acid solutions, including low concentrated and heat sensitive

Viscous solutions

Foaming products

Organic solvents and oils

Food and pharmaceutical products

Wastewater treatment

Process principle:

Under the action of gravity, the film flows down, gradually heating up.

After reaching the boiling point, an intense vapor release begins, additionally entraining the film and causing turbulence of its surface, thereby increasing the heat exchange efficiency.

In the separator, vapors and liquid are separated and drained from the apparatus.

Due to the better conditions of film formation and heat transfer compared to rising film evaporators, these devices are suitable for operation even at small temperature differences between the solution and the heating medium.