Reverse engineering

Reverse engineering (reverse engineering or reverse design) is the process of developing design documentation and/or a 3D model of a product based on a finished product sample. The manufacturing processes, imparting the required performance characteristics, repair and modernization of products are based on design documentation.

The main goal of reverse engineering is to obtain a complete set of design documentation for a finished product in the shortest possible time.

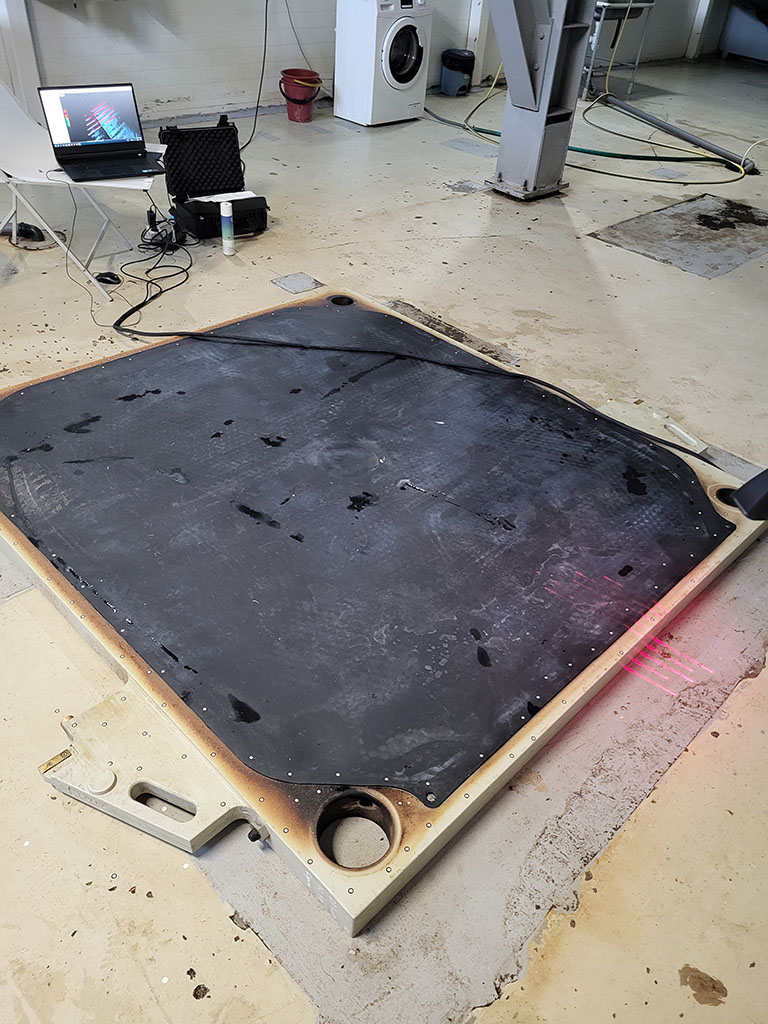

Our company provides reverse engineering services using modern equipment for 3D scanning of products. High-quality hardware and powerful software allow us to obtain 3D models with high accuracy and detail.

We scan equipment, measure it using contact methods, create accurate 3D models, and then prepare a complete set of design documentation.

We do all this in the shortest possible time and with the best quality.

You will be able to quickly begin production of a completely similar product!

What problems does reverse engineering solve?

-

Design of equipment analogue. Import substitution of products

Based on the provided sample, our specialists will prepare design documentation for the production of a Russian analogue. -

Modernization of existing equipment

By studying the configuration of the product, our specialists can select more modern components to replace the outdated ones and optimize the product for your production. -

Replacement or modernization of discontinued equipment

We will restore lost design documentation, expand the functionality of the product.

Advantages of reverse engineering:

Minimum time costs for the development of design documentation or 3D model;

Multiple reproduction. According to the design documentation obtained during reverse engineering, products can be manufactured an unlimited number of times in any production facilities depending on your needs;

The ability to refine the design, the manufacturability of individual units or parts as a whole, unification, etc.;

Reliability of supplies regardless of sanctions restrictions, instability of exchange rates, attachment to one supplier.

Stages of work execution:

Preparation of the product for scanning: disassembling the product into parts and determining the materials used.

Three-dimensional scanning and obtaining a 3D model.

Development of a working three-dimensional model.

Determining the characteristics and properties of the materials used.

Carrying out engineering calculations to confirm the required characteristics of an individual part or product.

Development of design documentation.

Development of the manufacturing process.

Manufacturing a prototype according to design documentation.

Testing the resulting product to confirm the calculated characteristics.

Reverse engineering is actively used in many industries:

Automotive industry;

Mechanical engineering;

Aviation;

Defense industry;

Medicine;

Oil and gas industry.