Catalytic oxidation system

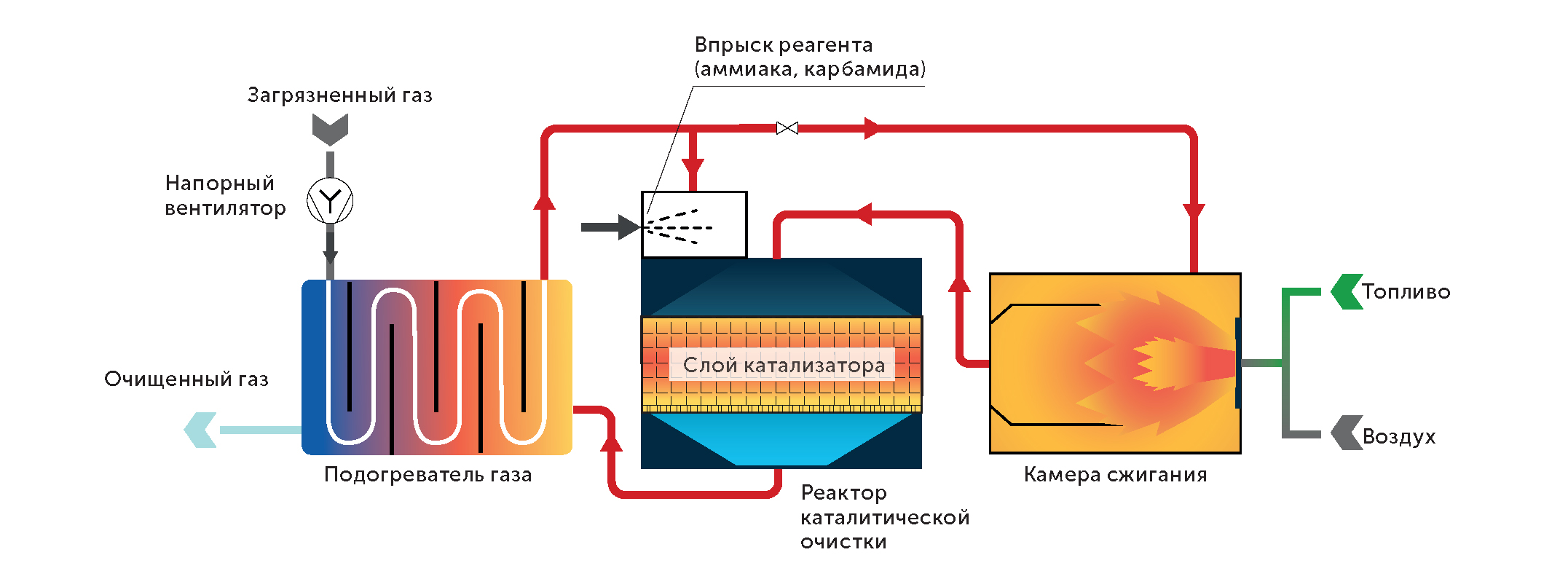

To save energy there is heating the contaminated gas mixture in the heat exchanger occurs, then the gas mixture is heated in the combustion chamber to the ignition temperature of the catalyst, and then directed to the catalyst. Purified gas mixture prior to discharge is directed to the heat exchanger where a portion of the heat of contaminated gas mixture.

Questionnaire

download

Advantages:

High efficiency

Low fuel consumption thanks to the regenerative system

Compact design

Scope of application:

Catalytic oxidation of gaseous pollutants emissions in chemical, petrochemical and other branch plants

Schematic diagram of catalytic oxidation of polluting gas impurities

Disposal emissions

Regenerative heat exchangers usage

Ensuring high efficiency