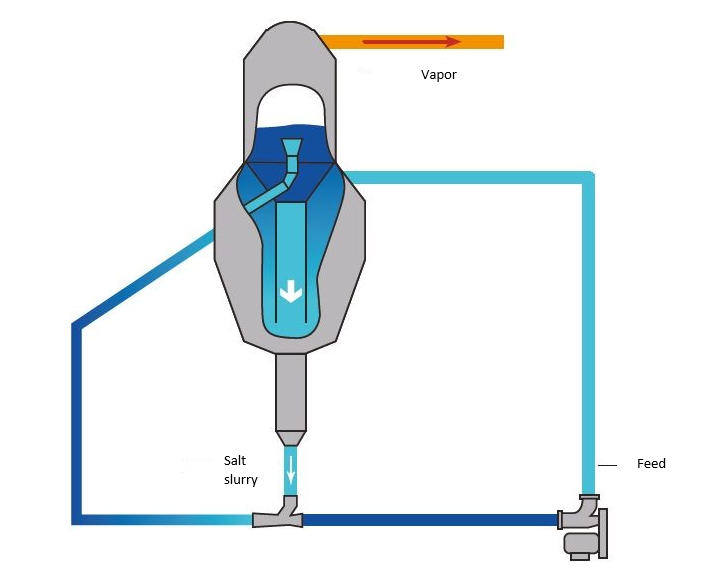

Indirect forced circulation evaporator/crystallizer

Advantages:

Combines the advantages of apparatus with an internal circulation pipe and fluidized bed

Lower energy consumption and lower cost compared to devices with an internal circulation pipe

Better process control and no problem of frequent cleaning compared to apparatus with a fluidized bed of crystals with a comparable crystal size distribution.

Process principle

Despite the significant advantages of fluidized bed crystallizers, these devices have a number of certain disadvantages, such as:

- 1. complexity of process management

- 2. the problem of deposits in the Central tube (caused by supersaturation of the solution in it in the absence of seed crystals in the circulating mother liquor) - requires very frequent cleaning of the device

- 3. significant overall dimensions compared to devices with forced circulation or internal circulation pipe.

These disadvantages are not found in indirect circulation devices that combine the advantages of these systems: the absence of contact of crystals with the circulation pump with high operational flexibility of processes.

In such devices, salt pulp with crystals from the growth chamber flows down under the action of natural forces, where it is partially discharged from the apparatus and partially sent to a mixing device, in which it is mixed with a circulating mother liquor (free from crystals) and sent to the upper part of the evaporating chamber of the crystallizer.

Due to the design features, the absence of contact between the crystals and the circulation pump is achieved and the problem of clogging of the central pipe of the crystallization chamber is solved because the solution is supersaturated in the presence of a sufficient number of seed crystals.