Vacuum belt filters

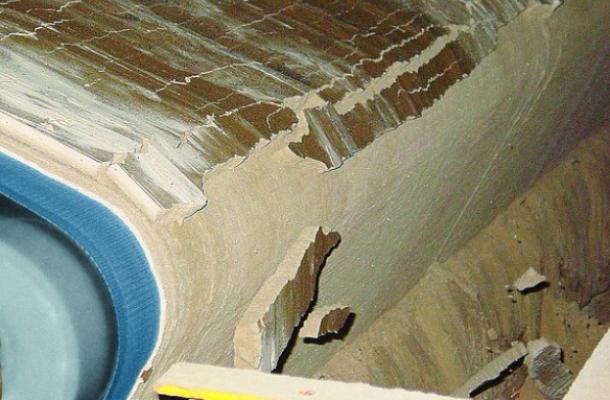

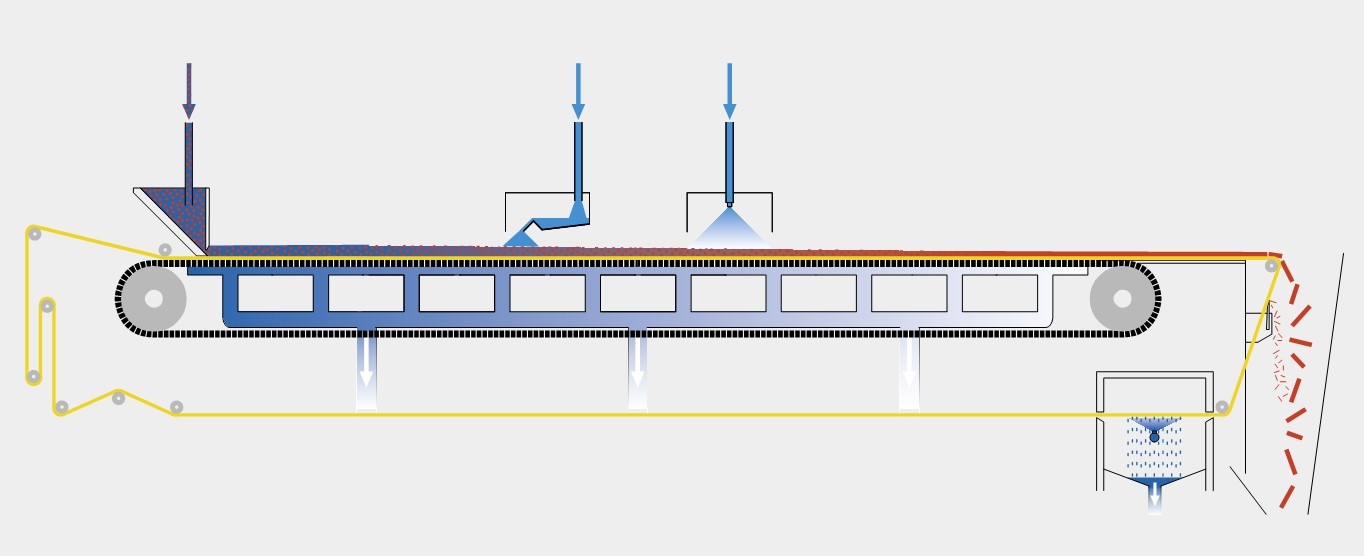

Vacuum belt filter is a horizontal vacuum filter of continuous action designed for separation of quickly deposited solids. Closed filter strip serves as a filtering medium. To support the filter cloth used rubber carrier belt, which has drain grooves for drainage of the filtrate.

The filter cake formed on the belt and can go through further treatment by washing (if necessary – many times in co-current or counter-current), evaporation, extraction or dry extraction. The filtrates from each stage of the process can be separated and subjected to processing separately, without mixing. On batch-of roll the filter cake is discharged. Cleaning of cloth occurs during reverse tape.

Questionnaire

download

Advantages:

Continuous, fully automatic principle of operation

High throughput

Low operating costs

Robust filter design

Scope of application:

Concentrates, washed product and secondary raw material yields

Off-gases desulfurization

Fly ash

Silica sand

Minerals: phosphorite, pyrite, ilmenite

Metals: cuprum, tin, zinc, plumbum

Iron ore

Coal

Other applications

Layout diagram:

The main standard sizes of belt vacuum filters:

Distinctive features

Durable design

Easy maintenance

High performance

Special design under the customer requirements