Electromagnetical vibrating feeders

Vibrating feeders are designed to provide uniform feeding and even distribution of material.

In the manufacture of vibratory feeders, pre-resonance tuning is performed, which stabilizes the vibration characteristics, which leads to an increase in the productivity and reliability of the equipment.

Vibratory feeders are manufactured in both suspended and supporting versions. All supplied vibrating feeders are hermetically sealed.

They are installed next to bins, conveyors, elevators, from which the material is directly fed to the feeders.

In the manufacture of vibratory feeders, pre-resonance tuning is performed, which stabilizes the vibration characteristics, which leads to an increase in the productivity and reliability of the equipment.

Vibratory feeders are manufactured in both suspended and supporting versions. All supplied vibrating feeders are hermetically sealed.

They are installed next to bins, conveyors, elevators, from which the material is directly fed to the feeders.

Questionnaire

download

Advantages:

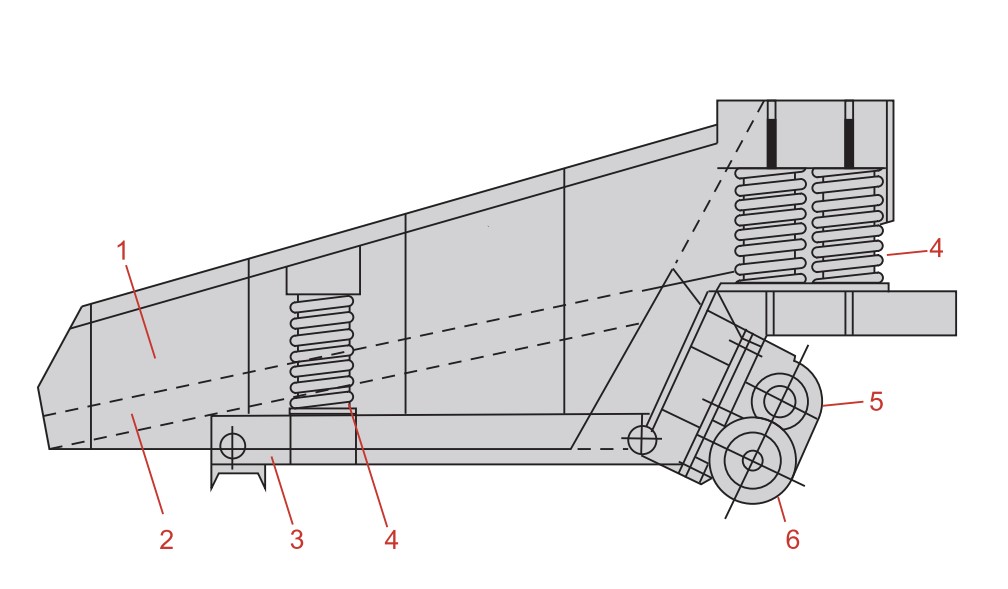

Simplicity of performance adjustment: adjustment is carried out by changing the voltage supplied to the coil of the electromagnet of the vibrating feeder, or by changing the tilt of the tray

No rotating parts in the structure

The possibility of starting under the blockage of the material of the feeding hopper, it can simultaneously serve as a shut-off device

Scope of application:

Feeding bulk and lumpy material from bins, silos and various conveyors to crushing, conveying or screening systems

Principle of working:

Electromagnetic vibrating feeders are driven by one electromagnetic motor located under the transport chute.