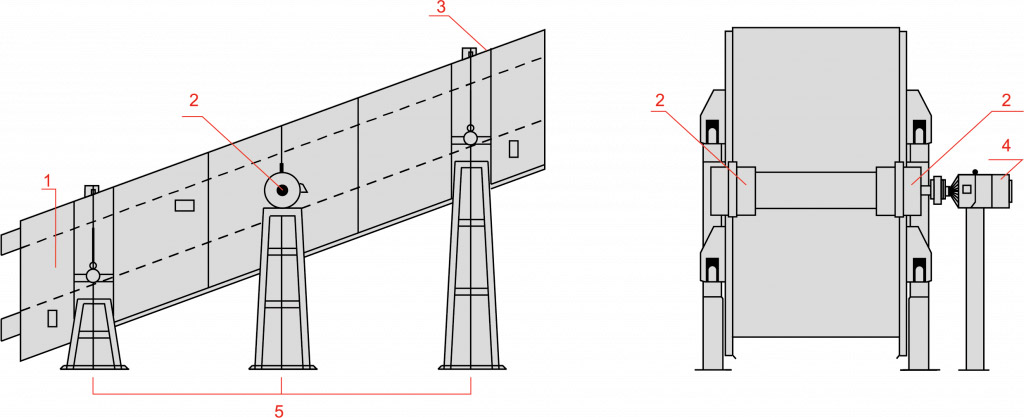

Inclined flat vibrating oscillating screens

Screening machines (screens) are manufactured in both open and closed versions. Closed systems are specially used in connection with extremely dusty, colored or toxic products or in connection with the requirement of a high degree of hygiene.

In the manufacture of screens, materials selected for each specific product are used. Thus, the screens of the screens are made either from stainless steel sheet or from carbon steel sheet with anti-corrosion paint coating. A special wear resistant coating can be provided for highly abrasive materials.

The choice of screening frames is carried out depending on the requirements of the Customer and the characteristics of the process:

- polyurethane sieves

- sieves with perforated plates

- wicker sieves (steel wire mesh)

In the manufacture of screens, materials selected for each specific product are used. Thus, the screens of the screens are made either from stainless steel sheet or from carbon steel sheet with anti-corrosion paint coating. A special wear resistant coating can be provided for highly abrasive materials.

The choice of screening frames is carried out depending on the requirements of the Customer and the characteristics of the process:

- polyurethane sieves

- sieves with perforated plates

- wicker sieves (steel wire mesh)

Questionnaire

download

Advantages:

Moderately high efficiency

Non-stop work

High maintainability and simplicity of design

Scope of application:

Coal

Hard rock mining products

Diamonds

Iron Ore

Principle of working:

Flat rocking screens consist of a rectangular box and a sieve, which is imparted by rolling from a moving cam mechanism. They are made in one-, two- and three-tiered.These vibrating screens are the ideal solution to maximize screening performance even under extreme conditions, both in terms of process and product.

The heavy construction is designed to withstand instantaneous, very high, intermittent and asymmetric loads.