Flexible hoses (hose lines)

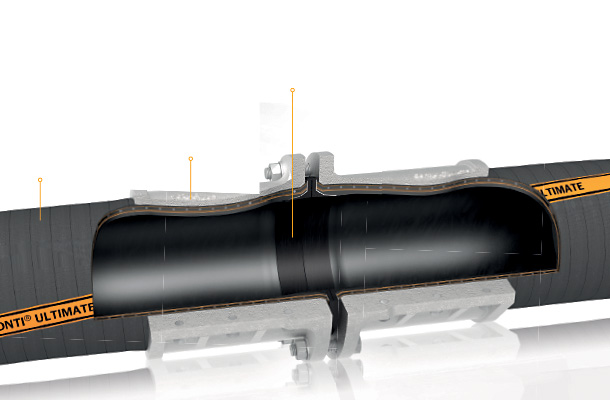

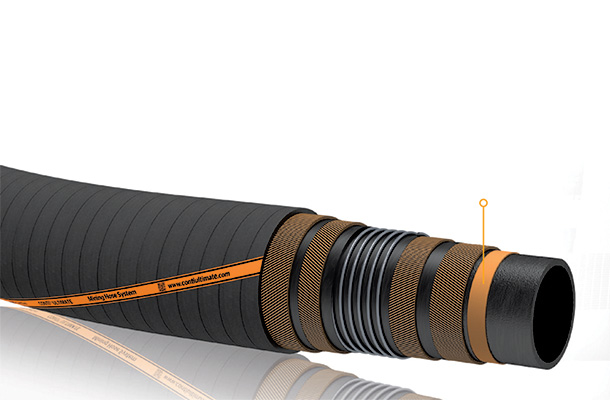

In technological processes of abrasive media pumping (transportation) are highly susceptible to thermal and mechanical influences. Special materials and design lines CONTI ULTIMATE SYSTEM can prevent deformation and destructive effect under the action of the abrasive. Rubber connecting hoses and CONTI are selected specifically for different production processes.

Transport lines from elastomers have significant advantages in using and maintenance compared with rigid pipes. Rubber is elastic, airtight and watertight, as well as more wear-resistant than metallic materials. Corrosion resistance and resistance to scum formation on the surface of the sleeve are also important advantages hoses CONTI ULTIMATE SYSTEM on hoses of metallic materials. Laboratory studies and practice have shown that the rubber has better abrasion resistance.

Advantages:

4 layers of textile binding braid (armoring) and built-in steel spiral along the entire length.

Very flexible, small bending radius.

Hoses of various lengths.

Scope of application:

slurries, slimes, powders, granules

pulp and other abrasive and dense medium

waste water

Technical specifications:

-

The hose is applicable in the project area suction and discharge

-

Pumping of sand, gravel and sludge

-

Burst margin 3.2 exceeds the working pressure

-

Operating temperature -40 °C to 80 °C

-

Smooth surface at the junction eliminates the disruption of the flow

-

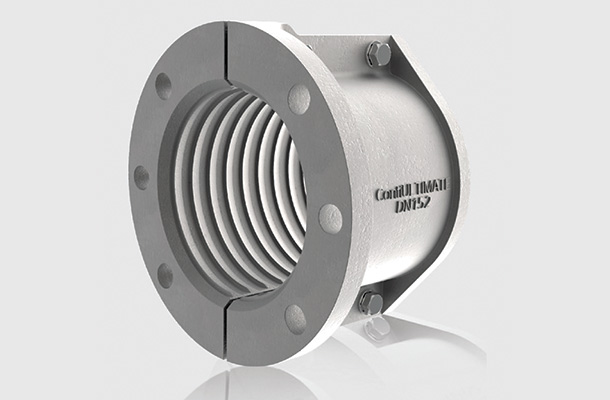

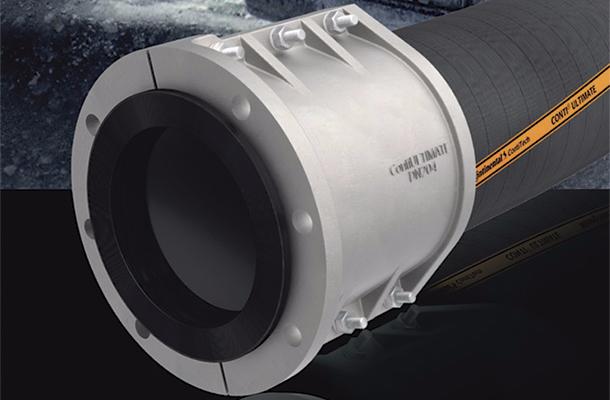

Non-disposable (re-usable) couplings

-

There is no contact between the transported medium and the flange

-

Easy installation and maintenance