Scrubbers

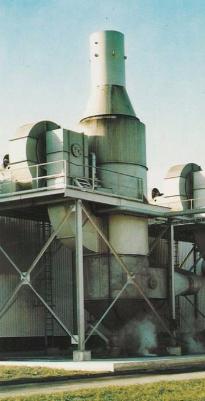

Scrubber Venturi

Venturi scrubber effectively combines the capabilities of cooling and cleaning of high dusty emissions. The Venturi scrubber with centrifugal droplet separator cleans the gas from micron and submicron particles with efficiency up to 99.9 %. The unique design of the offered Venturi scrubber is the ability to adjust the speed of the gas-liquid flow, and thus flow resistance in the throat of the Venturi scrubber, by varying the cross section through a drive with a gear lift. Thus achieved the desired efficiency of cleaning by creating the necessary size of the drops that are guaranteed to absorb contaminants and are separated from the gas stream. Due to the design of the scrubber and rational distribution of gas-liquid flows creates a turbulent regime and a highly developed contact surface, which allows effectively to absorb gaseous contaminants.

Centrifugal scrubber

Rotary scrubber operates as follows. The contaminated gas is tangentially fed into the lower part of the scrubber, passing section of the guide vanes.

Water for irrigation is fed countercurrent above the vanes, thus creating turbulence, which greatly increases the surface mass transfer and convective diffusion. Thus made high efficiency particulate irrigating fluid.

Rotary scrubber is applicable for highly efficient purification of gas emissions of large volumes containing both low and high concentrations of particulate matter and gaseous pollutants. It does not clog, has low maintenance cost.

Dynamic scrubber

Dusty gas phase is fed tangentially to the bottom of the scrubber, where the sedimentation of large particles. Next, the gas phase passes through a section of irrigated fluid vanes, which increases the rotation speed of the gas flow, which occurs due to deposition of medium sized particles. The liquid phase with trapped particles of dust flows into the lower part of the scrubber and the gas phase is sent to the fan. The fan is supplied to the liquid phase, spray them, due to which there is an integration of liquid droplets and the remaining smaller dust particles. Next, the gas stream is fed tangentially into the upper part of the scrubber where separation of the drops take place.

Rotary scrubber

The contaminated gas enters the rotary scrubber tangentially at the bottom part of the apparatus. Under the action of centrifugal force starts the capture of the largest particles of the gas phase. Then the gas flow passes the section of the vanes, which increases the rotation speed of the gas phase creates a turbulent regime, greatly increasing the surface mass transfer and convective diffusion.

Scrubbing liquid is fed over the guide vanes, the interaction of the gas and liquid phases is carried out in counterflow. Next, the gas stream increases the speed of rotation and interacts with the particulate phase of the scrubbing liquid spray spray device that enables fine purification of the gas phase. Caught thus, contaminants contained in the droplets of scrubbing liquid are discarded to the walls of the scrubber where the flow into the circulation tank and then circulating pump scrubbing liquid is re-fed to irrigation. If necessary, is added to makeup water.

Packed-bed scrubber

The principle of Packed scrubbers is based on the process of absorption of contaminants by irrigating film of liquid (absorbent) formed on the surface of the contact device (regular and irregular nozzles).

To achieve high efficiency and intensity of the cleaning process gases in Packed scrubbers (absorbers) are required for the absorbent (scrubbing fluid), as well as to develop the surface of contact of phases, create the necessary mode while maintaining acceptable flow resistance of the absorber (scrubber) and its dimensions.

"ChemInS" offers solutions from gases, gaseous compounds, in Packed absorbers (scrubbers) to meet the requirements of the devices to achieve high efficiency of the process (creating a developed contact surface phases and intensification of their interaction).

Place the equipment order

Запросить цену