Disposal of emissions containing styrene and other organic compounds

The purification of caloric gases is accompanied by the release of energy, which allows the use of thermal purification methods.

By using the heat generated by the oxidation of these compounds, we reduce operating costs.

In the process of drying polymers, rubbers or plastics and products, gaseous compounds can be released into the drying agent, while fine dust, fine aerosol of acid mists and fatty acids are carried away into the stream.

By using the heat generated by the oxidation of these compounds, we reduce operating costs.

In the process of drying polymers, rubbers or plastics and products, gaseous compounds can be released into the drying agent, while fine dust, fine aerosol of acid mists and fatty acids are carried away into the stream.

Gas purification is accompanied by the complexity of submicron particle size and high adhesion to internal surfaces, leading to complete blockages of the systems.

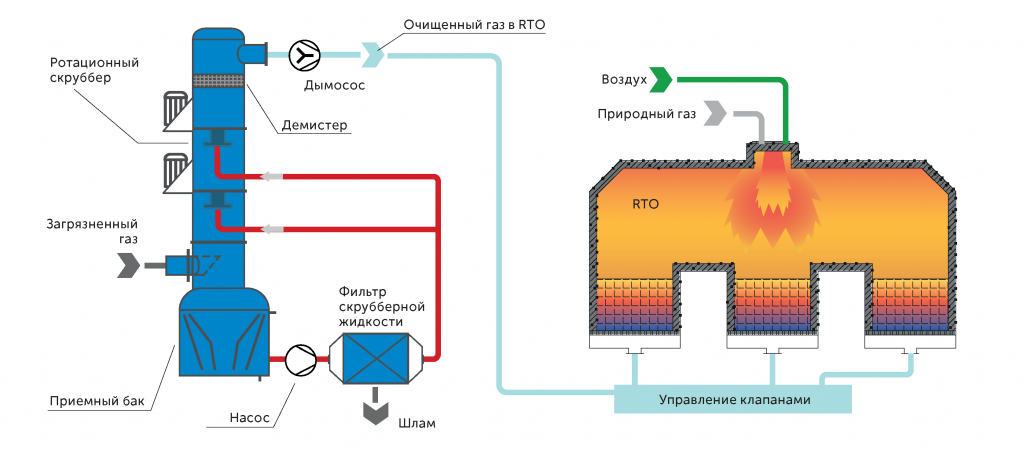

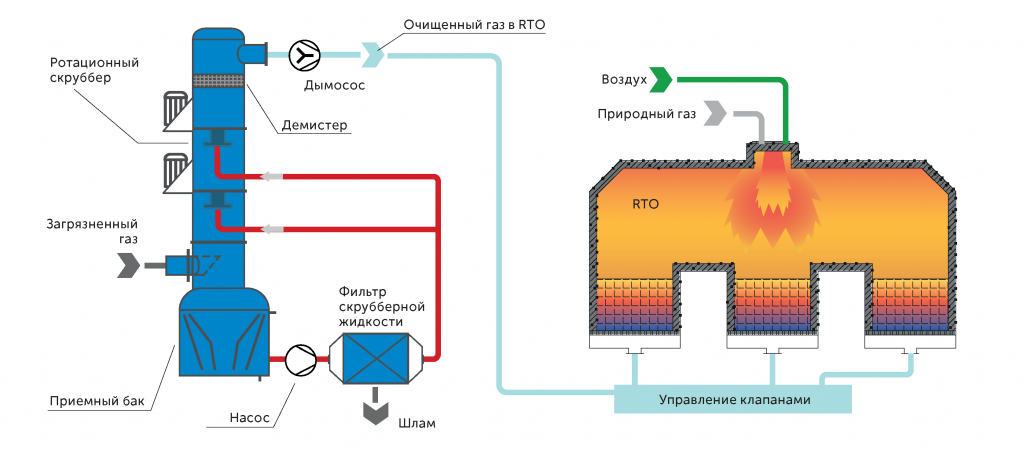

We use the following scheme to solve the problem:

1. Gas enters the rotary scrubber, where it is cleaned of submicron sticky particles, including acid droplets, with an efficiency close to 100%.

2. Fully aerosolized gas enters the regenerative thermal oxidizer (RTO) system, where organic compounds are oxidized with the release of heat, which accumulates in the ceramic medium and serves as a secondary heat source for new portions of gas, thereby reducing natural gas consumption.

At the same time, the rotary scrubber is equipped with all means to exclude incrustations (nozzleless irrigation, liquid films on the inner surfaces, etc.) and allows working in a circulating mode through the scrubber liquid until high concentrations of inclusions are reached.

3. The scrubber liquid circulates in a rotary scrubber, when critical concentrations for inclusions are reached, caused only by the pumping equipment, is removed to the filter unit, after which the clean filtrate is sent back to the scrubber, and the solid residue is removed or disposed of.

We use the following scheme to solve the problem:

1. Gas enters the rotary scrubber, where it is cleaned of submicron sticky particles, including acid droplets, with an efficiency close to 100%.

2. Fully aerosolized gas enters the regenerative thermal oxidizer (RTO) system, where organic compounds are oxidized with the release of heat, which accumulates in the ceramic medium and serves as a secondary heat source for new portions of gas, thereby reducing natural gas consumption.

At the same time, the rotary scrubber is equipped with all means to exclude incrustations (nozzleless irrigation, liquid films on the inner surfaces, etc.) and allows working in a circulating mode through the scrubber liquid until high concentrations of inclusions are reached.

3. The scrubber liquid circulates in a rotary scrubber, when critical concentrations for inclusions are reached, caused only by the pumping equipment, is removed to the filter unit, after which the clean filtrate is sent back to the scrubber, and the solid residue is removed or disposed of.