Integrated oil sludge processing system

Today, one of the main problems of oil refineries and petrochemical enterprises, from the point of view of ecology, is the continuous accumulation of oily waste or oil sludge. Disposal of such production waste requires the use of modern technological approaches, due to the constantly tightening environmental standards.

Today, the most common and simple method of disposal is incineration in furnaces of various designs, followed by purification of waste gases from the process. In addition to low environmental performance, this method is characterized by the loss of valuable hydrocarbons contained in the feedstock, which could be returned to the processing process

Today, the most common and simple method of disposal is incineration in furnaces of various designs, followed by purification of waste gases from the process. In addition to low environmental performance, this method is characterized by the loss of valuable hydrocarbons contained in the feedstock, which could be returned to the processing process

We offer a comprehensive oil waste processing system based on anaerobic thermal desorption process technology.

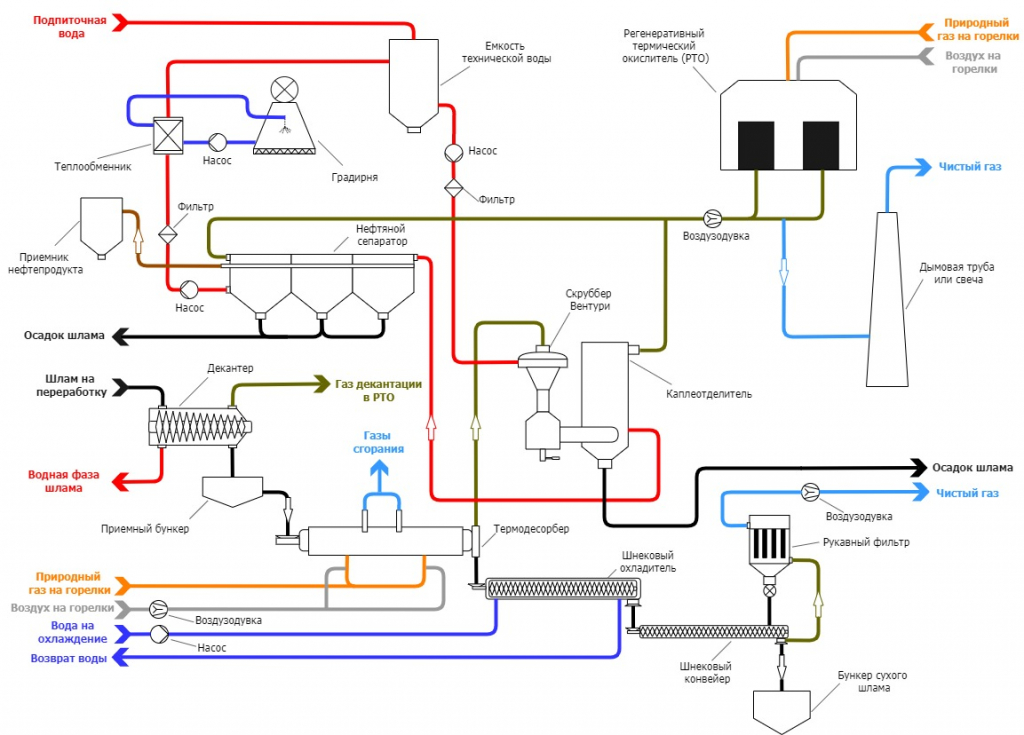

The peculiarity of the process is that the feedstock does not come into direct contact with the combustion source, but contacts it through the wall, thereby avoiding the formation of a large amount of toxic products, as well as extracting valuable hydrocarbons with the possibility of their involvement in subsequent processing.

The non-condensed gas phase undergoes a complex wet cleaning system, with further filtration or, if necessary, a regenerative thermal oxidation (RTO) system, which ensures almost complete absence of harmful emissions into the atmosphere. The watered oil sludge undergoes a decantation stage, after which it enters the receiving feed bin, and then into the thermal desorber.

The solid residue is cooled in a screw-type water cooler, and then transported to a storage tank. The evaporated gases, from the thermal desorber, go to the stage of wet cleaning in the Venturi scrubber, where they are condensed, and also cleaned from sludge dust. Water and condensed hydrocarbons are sent to an oil separator where the water and oil phases are separated.

The hydrocarbon part is pumped out into the receiving tank, and the water is returned to the circulation loop. Non-condensed gases from the droplet separator, oil separator, as well as decantation gases enter the thermal oxidation stage, after which they are dispersed in the atmosphere.

The peculiarity of the process is that the feedstock does not come into direct contact with the combustion source, but contacts it through the wall, thereby avoiding the formation of a large amount of toxic products, as well as extracting valuable hydrocarbons with the possibility of their involvement in subsequent processing.

The non-condensed gas phase undergoes a complex wet cleaning system, with further filtration or, if necessary, a regenerative thermal oxidation (RTO) system, which ensures almost complete absence of harmful emissions into the atmosphere. The watered oil sludge undergoes a decantation stage, after which it enters the receiving feed bin, and then into the thermal desorber.

The solid residue is cooled in a screw-type water cooler, and then transported to a storage tank. The evaporated gases, from the thermal desorber, go to the stage of wet cleaning in the Venturi scrubber, where they are condensed, and also cleaned from sludge dust. Water and condensed hydrocarbons are sent to an oil separator where the water and oil phases are separated.

The hydrocarbon part is pumped out into the receiving tank, and the water is returned to the circulation loop. Non-condensed gases from the droplet separator, oil separator, as well as decantation gases enter the thermal oxidation stage, after which they are dispersed in the atmosphere.

Scheme of integrated processing of oil sludge: