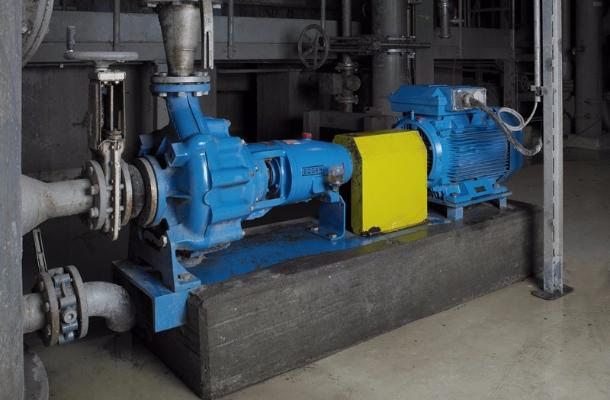

Turo® VORTEX EGGER PUMPS TA

Turo ® vortex Egger pumps have a completely open spherical channel. Only 15% of pumped liquid is in contact with the impeller. 85% of the fluid passes through the pump housing without contact, what significantly reduces possible cutting wear, abrasion.

This type of pumps is well established when applied as a feed pump in systems with variable resistance, for example when applying to feed the filter presses. The increase in resistance in the pressure pipe up to stop the flow, does not cause vibration or other negative effects, adverse events.

Egger pumping equipment is manufactured in accordance with individual, custom projects. The selection of design, materials and seals depends on the requirements list, performance specification. Structurally, the pumps can be manufactured in different types: horizontal, vertical, semi-submersible and submersible with electric or hydraulic drive.

For operation at high temperatures and pressures Egger develops and produces special series of pumps, including those for hazardous areas and in a gas tight version.

Video review

Questionnaire

download

Advantages:

The open channel and the blockages absence

The contact of the medium with the impeller 7 times reduced

Resistance to abrasive wear

High performance, longer-lasting efficiency

Scope of application:

Chemical industry

Fabric industry and fiber production

Pulp and paper industry

Petrochemical industry

Smelting and power industries

Raw sewage

Municipal and industrial wastewater

Sugar plant

Technical specification:

-

Nominal dimensions (DN): 32–200 mm

-

Capacity (Q): up to 900 m3

-

Discharge head (H): up to 140 m

-

Operating pressure (P): up to 30 (100) bar

-

Working temperature (T): up to 180 (500) °C

* there are the values for special series of pumps indicated in parentheses

Unique design feature

Open channel and the absence of blockages

Resistance to abrasive wear

High, sustained efficiency

Gentle pumping

Smooth and quiet running of the pump

Reliability and long service life

Features of the ta range pumps

Pumped medium

Crystal suspended mixtures

Abrasive and corrosive fluids

Viscous medium

Sludge and suspension with a high content of fibers

Municipal and industrial wastewater

All types of slurries