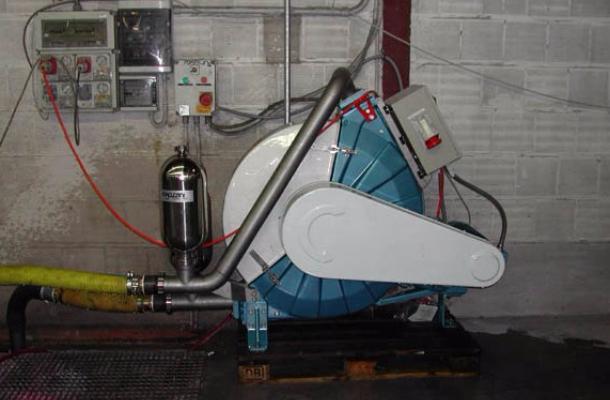

Peristaltic / flexible hose pumps

Hose-type pumps, often called "peristaltic", providing the possibility of pumping liquids with solid particles, viscous and pasty liquids.

Using peristaltic pumps the only solution for the full range of fluids that must maintain their purity in the process of moving and should not come into contact with the mechanical part of the pump, because of its extreme chemical aggressiveness or danger.

Peristaltic pump gently pumps the product that is ideal for sensitive to mixing, fragile chemicals or food products. Pumps provide uniform flow, which significantly affects the quality of the finished product.

Such kind of pumps serve at chemical industries as an alternative to conventional plunger or piston pumps. Worldwide peristaltic pumps are used for mine water pumping and the rock sludge handling.

Questionnaire

download

Advantages:

Does not require periodical lubrication.

High efficiency compared to other flexible hose pumps.

Mechanical parts are not in contact with fluid and do not pollute the pumped product.

Working hose easy replacement without waste oil or glycerin solution drain.

Changes only the working hose without the pump dismantling.

Possible reversible operation of the pump.

Can operate in "dry-running" without damage.

Has no valves, liners and seals.

The pump over product does not react with oxygen in the air and oxidize.

Scope of application:

Chemical production (acids, alkalis, corrosive media, sewage drain)

Pottery industry (clay suspension. ceramic glaze)

Sewage treatment plant

Winemaking (whole or treated grapes, fermentation residue, bentonite)

Food production (curds pumping, sucrose syrup, molasses, balsamic vinegar, olive oil, etc.)

Cosmetic and pharmaceutical production

Metallurgical industry

Pulp and paper industry

Paints and pigments, ink

Mining industry