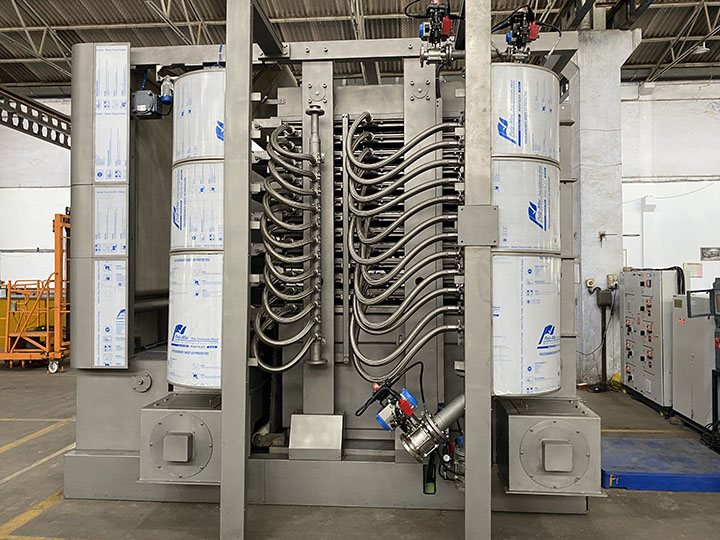

Automatic Vertical Pressure Filter

Automatic Vertical Pressure Filter is ultimate equipment designed to handle flammable, toxic and corrosive material since they are autoclaved and designed for hazardous environment when high pressure and safe environment is required. Like wise they may be readily jacketed for application whenever hot or cold temperature is to be preserved.

Video review

Questionnaire

download

Booklet

download

Advantages:

Improvement in productivity

Reduction in energy consumption

Superior product Properties

High Yield

Emission avoidance

Scope of application:

Pharmaceuticals

Food Processing

Waste Processing

Effluent Treatment

Minerals

Mineral Concentrates

Chemical Processing

Design Features:

The horizontal plate design results in even distribution of slurry, wash liquid and most effective air penetration with no risk of cake cracking.

Fully automatic. Resulting in consistent performance in terms of through put, i.e. higher productivity. Once downstream and upstream equipment integrated with optimized process parameters leading to highest quality products, with lowest moisture and yield. No operator required, eliminates exposure of operator to chemical & equipment.

As the driest cake is produced of all filtration methods, Lower energy costs as it eliminates or reduces the requirement of dryers.

Ultra filtration wash system eliminates plant effluent system.

The machine can be built with features confirming to explosion proof standards.

Based on service requirements non corrosive, corrosive or highly corrosive application, machine can be built with various stainless steels & high strength materials.

Mode of Operation:

Filtration

Squeezing

Cake Wash

Post Wash Squeezing

Air – Blowing

Cake Discharge & Cloth Washing