Venturi scrubber

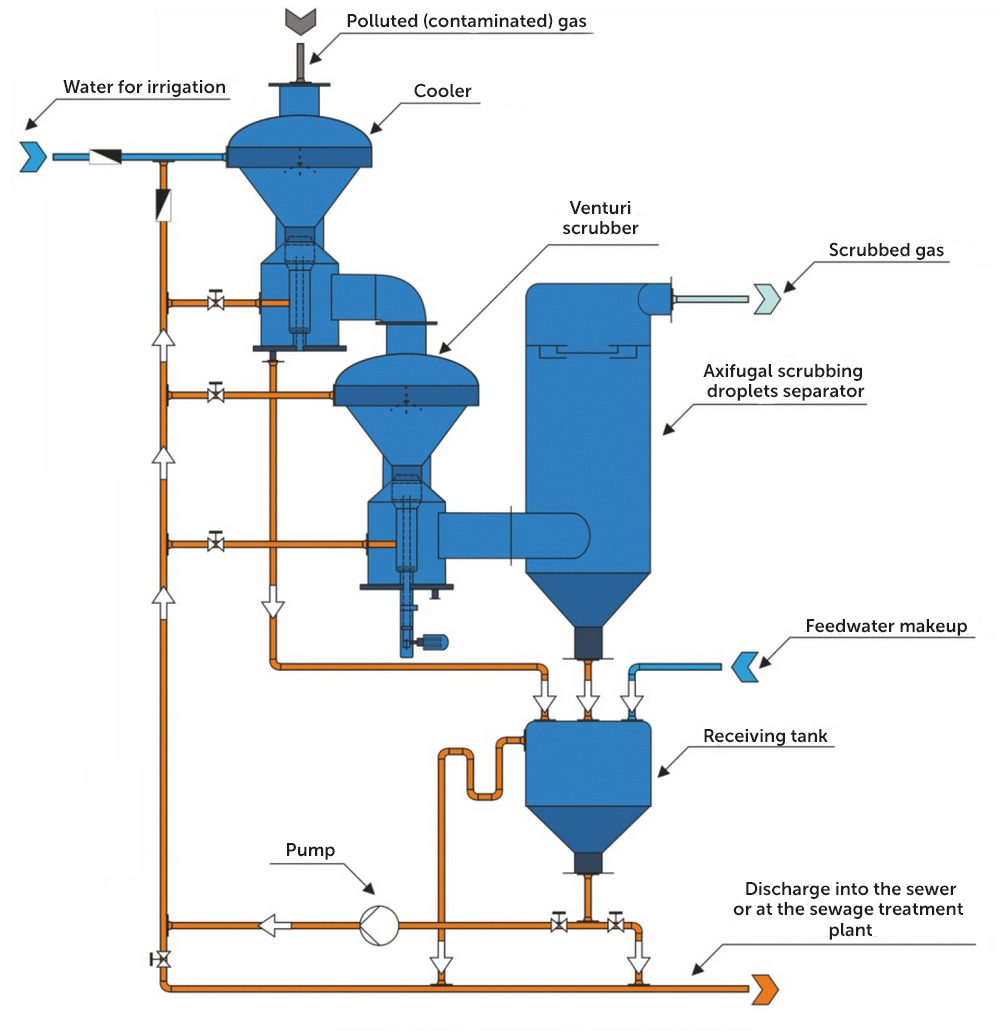

Venturi scrubber effectively combines the capabilities of cooling and cleaning of high dusty emissions. The Venturi scrubber with centrifugal droplet separator cleans the gas from micron and submicron particles with efficiency up to 99.9 %. The unique design of the offered Venturi scrubber is the ability to adjust the speed of the gas-liquid flow, and thus flow resistance in the throat of the Venturi scrubber, by varying the cross section through a drive with a gear lift. Thus achieved the desired efficiency of cleaning by creating the necessary size of the drops that are guaranteed to absorb contaminants and are separated from the gas stream. Due to the design of the scrubber and rational distribution of gas-liquid flows creates a turbulent regime and a highly developed contact surface, which allows effectively to absorb gaseous contaminants.

Questionnaire

download

Advantages:

Stable operation with fluctuations of the gas flow

Steady work with sticky, sticky dust

Gas flows with a temperature of over 1000 °C cooling

Low operating costs

Scope of application:

coal dust and other dust species

dust food enterprises (tobacco manufacturing, sugar, etc.)

dust, smoke after incineration furnaces, etc.

metal oxides, heavy metals

salts (nitrates, sulfates, carbonates, chlorides) of the enterprises of mineral fertilizers, etc.

dust from the enterprises for manufacture of building materials

organic dust from pharmaceutical companies

acid mists at the chemical and petrochemical enterprises

Scheme for dedusting hot gases

Design features and principle of operation proposed by us Venturi scrubber:

Gas and liquid streams feeding method

Process set efficiency maintaining / the predetermined process efficiency (> 99 %)

Guaranteeing separation of drops

Waste water minimization

Cooling in a venturi scrubber