Centrifugal / rotary scrubber

Rotary scrubber operates as follows. The contaminated gas is tangentially fed into the lower part of the scrubber, passing section of the guide vanes.

Water for irrigation is fed countercurrent above the vanes, thus creating turbulence, which greatly increases the surface mass transfer and convective diffusion. Thus made high efficiency particulate irrigating fluid.

Rotary scrubber is applicable for highly efficient purification of gas emissions of large volumes containing both low and high concentrations of particulate matter and gaseous pollutants. It does not clog, has low maintenance cost.

Questionnaire

download

Advantages:

Stable operation by the gas flow fluctuations and the contaminant concentration

High separation efficiency

Steady work with abrasive dust

Low hydraulic resistance

Scope of application:

Cleaning and deodorizing of chemical and petrochemical enterprises, metallurgy, mining, waste incineration, food and other related industries emissions

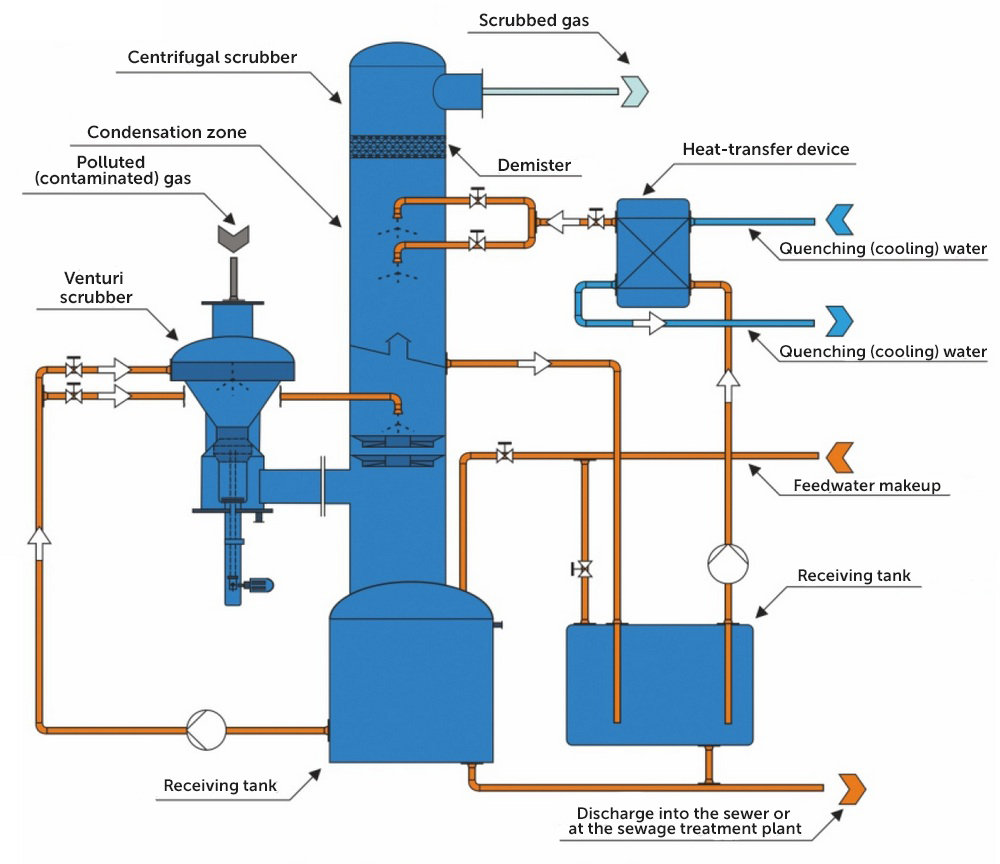

Scheme of acidic emissions purification

Offered by our company centrifugal scrubber design features and principle of operation:

Intensification of mass transfer (increasing efficiency of gas purification) without hydraulic resistance increasing

Passive contact elements absence (packing, plates, etc.), leading to the scrubber free cross section clogging