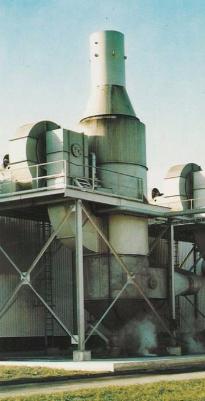

Dynamic scrubber

Dusty gas phase is fed tangentially to the bottom of the scrubber, where the sedimentation of large particles. Next, the gas phase passes through a section of irrigated fluid vanes, which increases the rotation speed of the gas flow, which occurs due to deposition of medium sized particles. The liquid phase with trapped particles of dust flows into the lower part of the scrubber and the gas phase is sent to the fan. The fan is supplied to the liquid phase, spray them, due to which there is an integration of liquid droplets and the remaining smaller dust particles. Next, the gas stream is fed tangentially into the upper part of the scrubber where separation of the drops take place.

Questionnaire

download

Advantages:

High separation efficiency

Absorption of gaseous pollutants

Stable operation by the gas flow fluctuations

Integration into existing ventilation systems

Scope of application:

Cleaning and deodorization of chemical and petrochemical enterprises, metallurgical, mining, ore dressing, waste incineration, food and other related industries emissions

Technical specification:

capacity: from 1,000 to 100,000 m3/h

particle size: > 2 microns

residual dust: < 20 mg/m3

efficiency: > 99,9 % (depending on particle size)

hydraulic resistance: 1.5 kPa

Design features and principle of operation our proposed dynamic scrubber:

99.99 % efficiency achieving

To ensure its own thrust