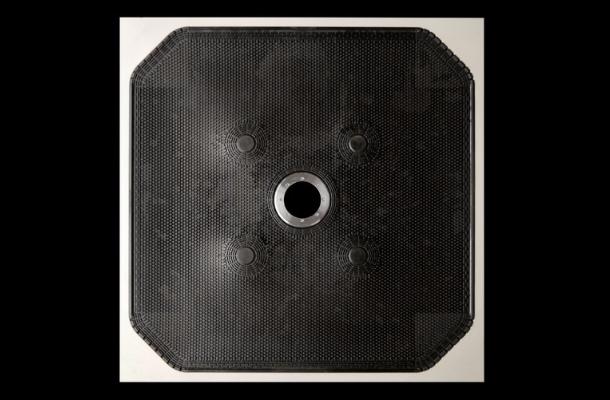

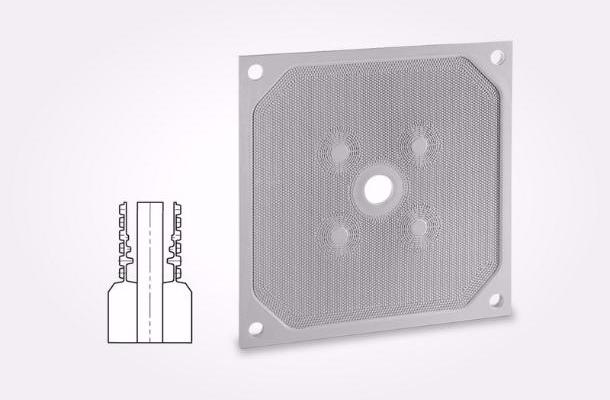

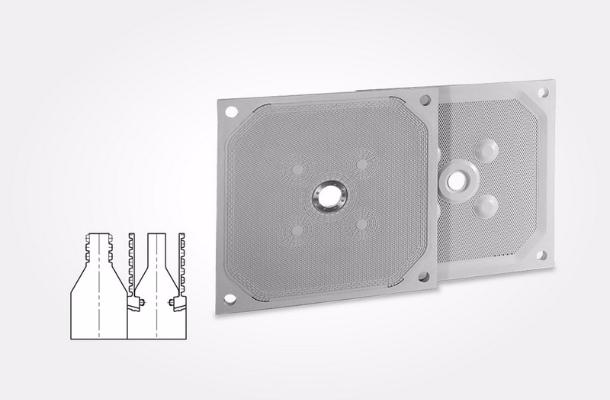

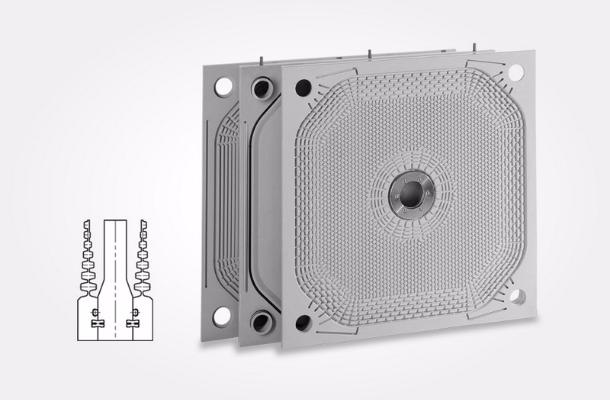

Membrane plates

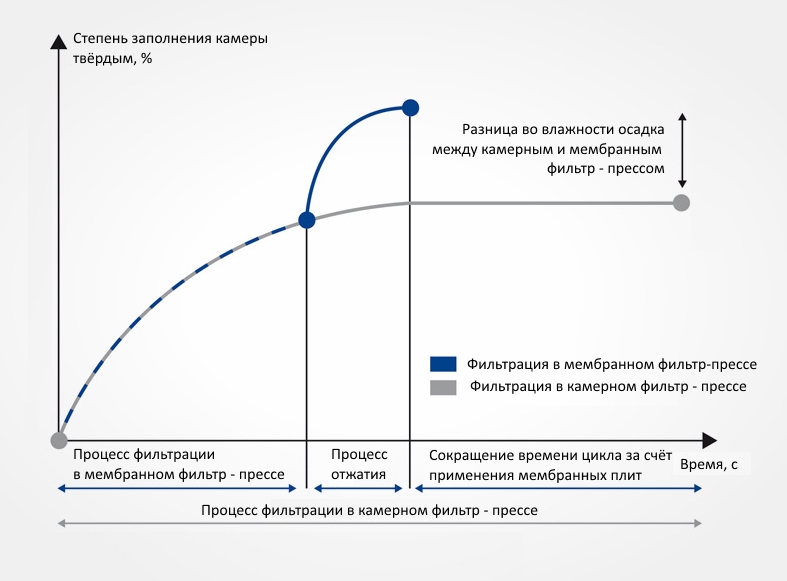

Membrane filter plates Lenser allow execute an additional mechanical pressing of cake. For a short period of time from 2 to 5 minutes under pressure of water or air under the diaphragm (membrane) greater than the 2-4 bar pressure feed pump, sludge pressed sufficiently large amount of filtrate. Thus, it is possible to significantly reduce the moisture content of the filter cake compared to the filtration chamber plates, and to reduce the cycle time. The membrane plates are also used, if necessary, blowing or washing of the cake to make it uniform in all directions resistance.

The movable diaphragm membrane can be welded without the possibility of replacement if damaged, and removable. Membrane filter plates are manufactured with any type of feed suspension and dimensions from 400 to 3000 mm.

Questionnaire

download

Advantages:

High separation efficiency of the slurry into liquid and solid phase. Low moisture content of cake.

High quality of the properly selected filter plate material. Manufacturer of granulated polypropylene - Lyondell Basell (Germany)

Geometry – the pattern at drainage surface provide bigger "live" surface area of the filter cloths in comparison with competitors.

The optimal area of the sealing surface guarantees maximum value of the chamber filter square and a full set of plates.

The patented technology of three modifications polypropylene body plate welding, the sealing surface and the membrane itself.

The possibility to produce a membrane filter plates for filter presses of any manufacturer.

Development of individual design solutions under technological conditions of the customer

Scope of application:

Non-ferrous metallurgy

Coal industry

Sugar industry

Wastewater from electroplating industry

Chemical industry

Production of mineral fertilizers

Dewatering of industrial and municipal effluents.

And others.

Chamber and membrane filter press cycle time comparison

Basic principles of diaphragm plate and diaphragm material design selection

Design bloc – welded membrane

UM bloc design - welded membrane

RUD design – removable membrane (diaphragm) without the sealing surface.

RUM design – removable membrane (diaphragm) with sealing surface.