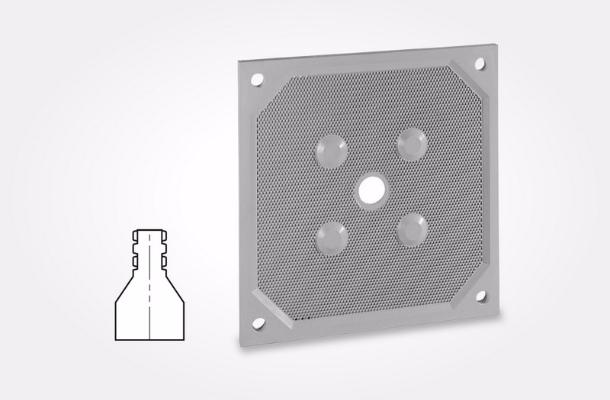

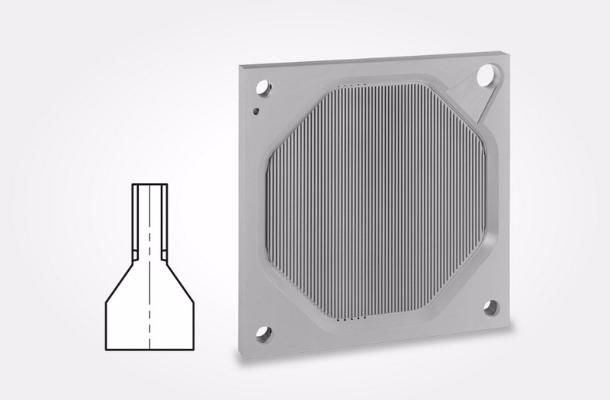

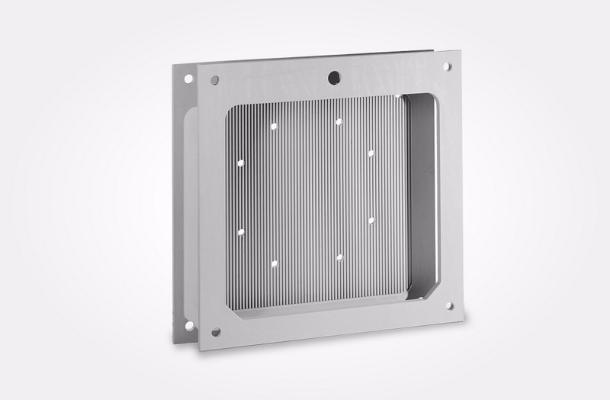

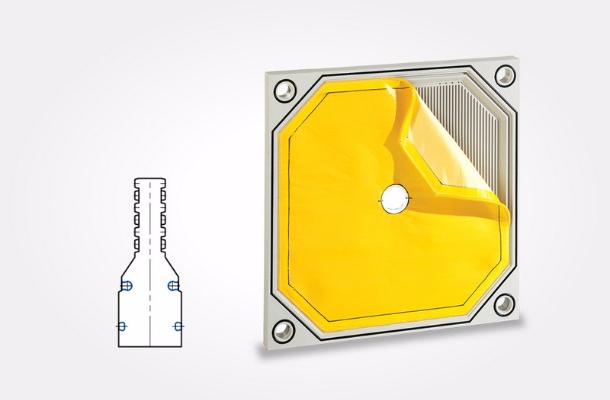

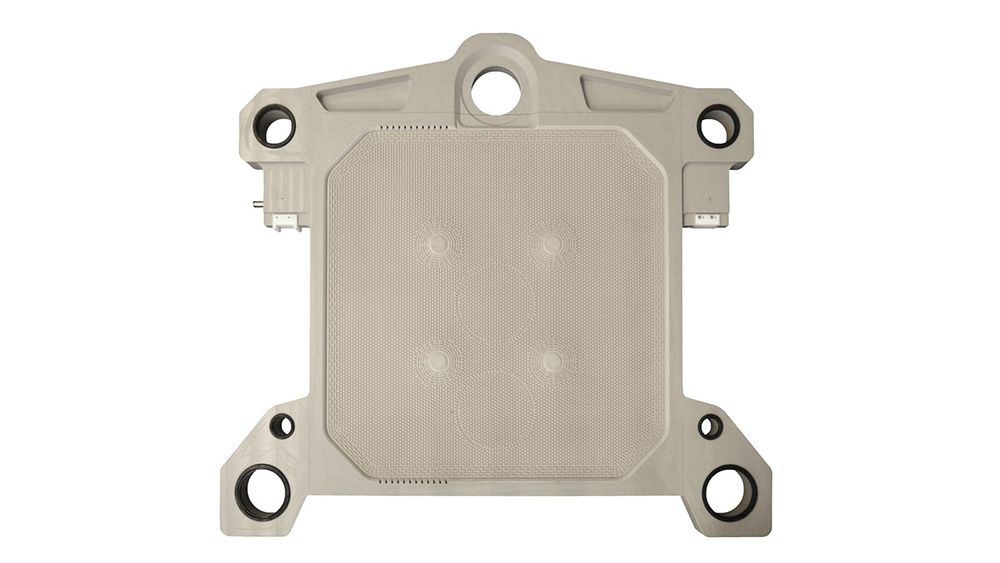

Chamber plates

Chamber plates are the most common type of filter plates for filter presses. They have found wide application in the food industry, ceramics, waste water dewatering, coal and chemical industry. Chamber filter press came to replace the outdated frame filter-presses with wooden or cast-iron plates. This type of filter elements allows you to get away from the participation of staff in the process of unloading the filter press and to automate the filtration process in the event of low adhesion of the precipitate to the filter cloth. Chamber filter presses are the ideal solution for filtration of suspensions, where there are no stringent requirements on the moisture content of sludge, necessity of washing and drying of the filter cake. Chamber filter plates are manufactured with different sizes (from 400x400 to 2500х2500 mm), a channel arrangement of a suspension and discharge of filtrate.

Video review

Questionnaire

download

Advantages:

High density - uniformity of the pressing filter plate

High quality of the properly selected material plate. Manufacturer of granulated polypropylene - LyondellBasell (Germany)

Geometry - drainage surface pattern provides more "live" surface area of the filter cloths

The optimal area of the sealing surface guarantees maximum value filter square of chamber and a full set of plates.

Scope of application:

Ceramic / Kaolin industry

Cement industry

The coal industry

Brewing

Non-ferrous metallurgy

Wastewater from electroplating

Chemical industry

Mineral fertilizers production

Sugar industry

Dewatering of industrial and municipal effluents

And others.

Why definitely Lenser Filtration GmbH (Germany)

High quality of raw material for filter plates compression molding

Modern equipment and the right technology for the plates compression molding

Huge experience of Lenser Filtration GmbH designers

Ability to see with your own eyes