Filter cloth manufacture

Fabrication of filter cloth is a complex and multistage process, from filament basic material selection to finishing treatment of the end product. Filter cloth acts as a filtering partition and should combine the optimal ratio of the filtration flow rate and clarity of filtrate. In addition, by no means unimportant role plays the chemical and mechanical resistance of the material, the efficiency of regeneration, a minimum adhesion of sludge and subset of other parameters, which together determine the selection of a actual type of filter cloth for a specific process.

ChemInS LLC controls and can adjust the production of filter cloth from manufacture of threads to the type and the method of final processing of the fabric, glossing parameters and thermostabilisation, heat setting. That is why we can supply filter cloth and their products for a specific filtration process to achieve maximum efficiency.

Questionnaire

download

Advantages:

Work directly with the manufacturer of the full cycle: from yarn to purchased item

Own laboratory and pilot equipment for testing at the customer's enterprise availability

Extensive experience in the field of filtration on different type of equipment

References in various industries

Scope of application:

horizontal filter presses

vertical (tower) filter presses

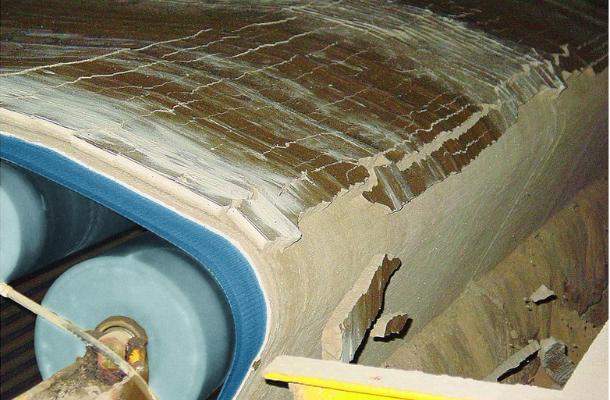

belt filter presses

band vacuum filters

candle (bag / pitch fumes bag) filters

disk vacuum filters

leaf filters

drum filters

The types of materials and air permeability values depending on the type of weaving / material

Application

Filtration through filter cloth is used in many different kind of industries. Its task is the separation of solid particles from liquid or gas according to the principle of the sieve mechanism. In addition to mechanical processes often need to take into account the physical and chemical aspects of filterable media: the adhesion of the produced sludge, potential of colloidal components. Depending on the type of equipment that uses a filter cloth, and the conditions of the process to the finished filter element must meet different requirements.

The presence of our company experience in the selection and supply of filter cloths and products from them to various industry sectors for different kind of equipment is a guarantee of quality of products we offer and guarantee efficient operation of your filtration equipment.

Questionnaire

download

Scope of application:

Mining:

- dehydration of metal concentrates (copper, zinc, lead, nickel, cobalt, antimony, etc.)

- tailing slimes dewatering

- air purification in zones of ore unloading and transportationChemical industry:

- mineral fertilizers manufacturing

- production of organic and inorganic pigments, dyes and coloring agents

- titanium dioxide production

- production of soda, calcium chlorite, etc.Metallurgical industry:

- production of non-ferrous metals: hydrometallurgy, electrolysis

- ferrous metallurgy / steel

- control filtration in the precious metals fabrication

Food industry:

- sugar factory

- beer and kvass

- oil manufactureEcology:

- electroplating waste-water treatment

- waste water treatment of CHPP (Central Heating and Power Plant)

- industrial wastewater dehydrating

- municipal sewage dewatering of public owned treatment works

Types and sizes of filter cloths

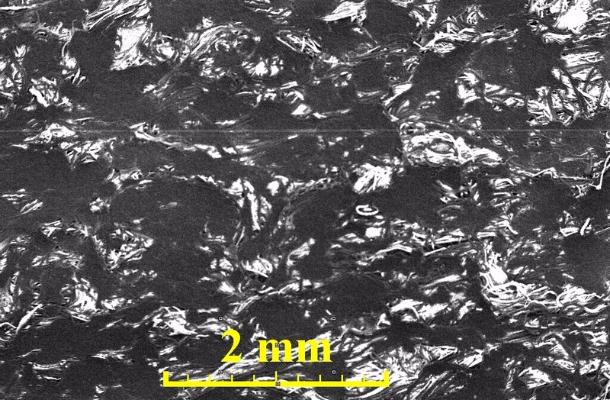

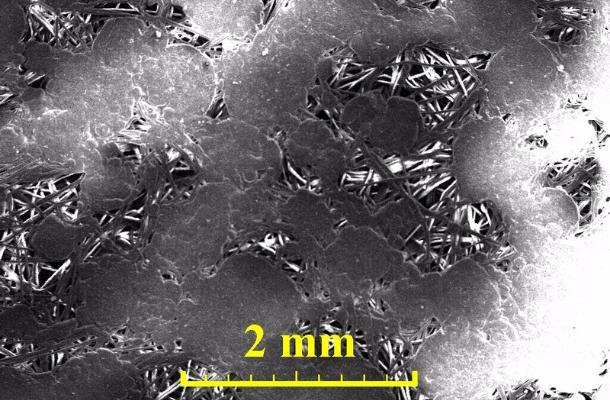

Filter cloths are divided by the type of weave and type of yarn. In addition woven materials can also be used non - woven materials, needle-punched, but mainly in liquid filtration of particles smaller than 1 micron and bag filtration of the gases.

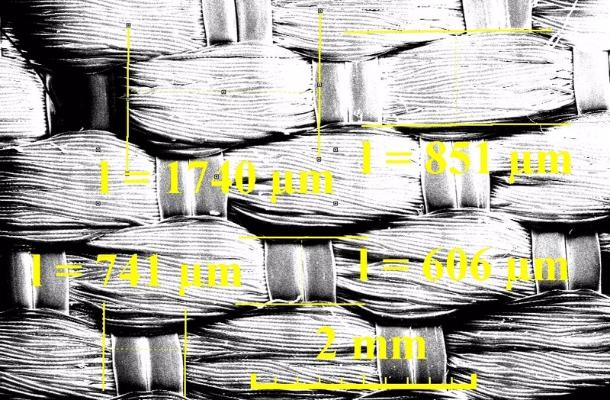

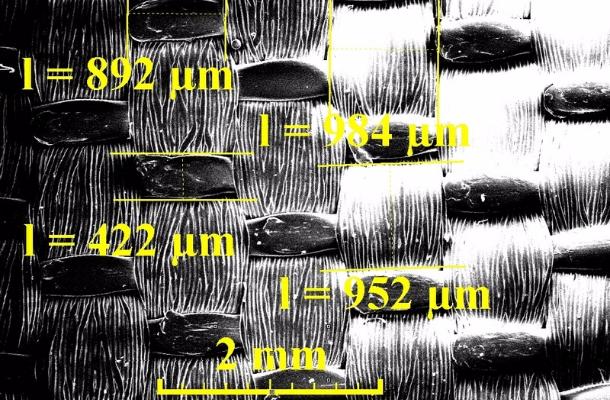

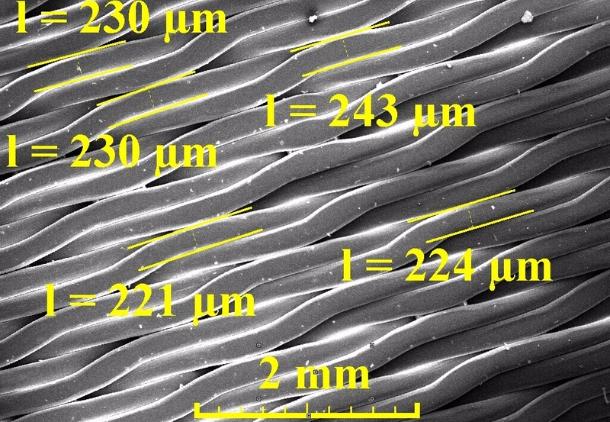

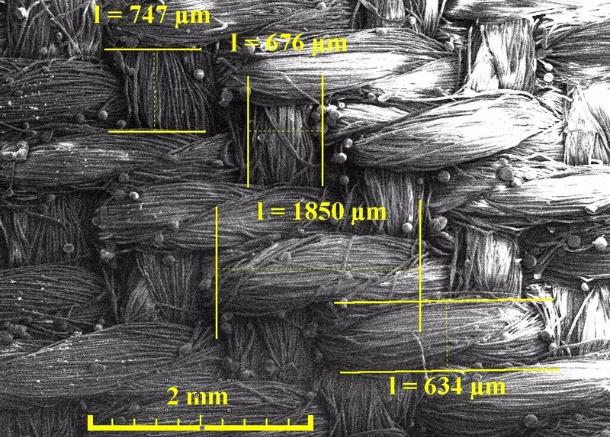

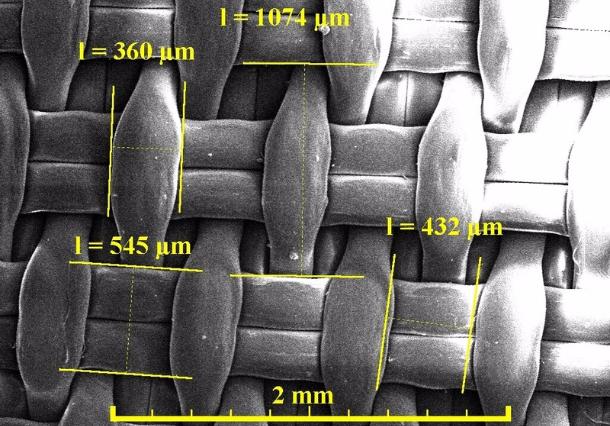

Fabrics made from multifilament and monofilament yarns. Depending on their combination in the weaving are mostly isolated multifilament fabric, monofilament fabric and mono/multifilament fabric.

Multifilament has a higher retention monofilament fabric promotes better convergence of sediment. Mono/multifilament fabric combines the advantages of two other types, but produced in a limited range of air permeability.

Our company supplies all of the above mentioned types of filter fabrics and finished products for any type and size of filtration equipment.

Questionnaire

download