Belt dryers

Questionnaire

download

Advantages:

work with fragile, molded and granular products without breaking the structure

adjustable gas temperature, speed and direction for each drying section

installation of additional equipment for mechanical impact on the product

energy saving due to drying gas recycling

different types of processing in one line

variety of processes and applications

exact processing time

Scope of application:

extrudates

molded blanks

granules

crumbs

ore chunks

pastes

feeds

food products

lumps

Process principle:

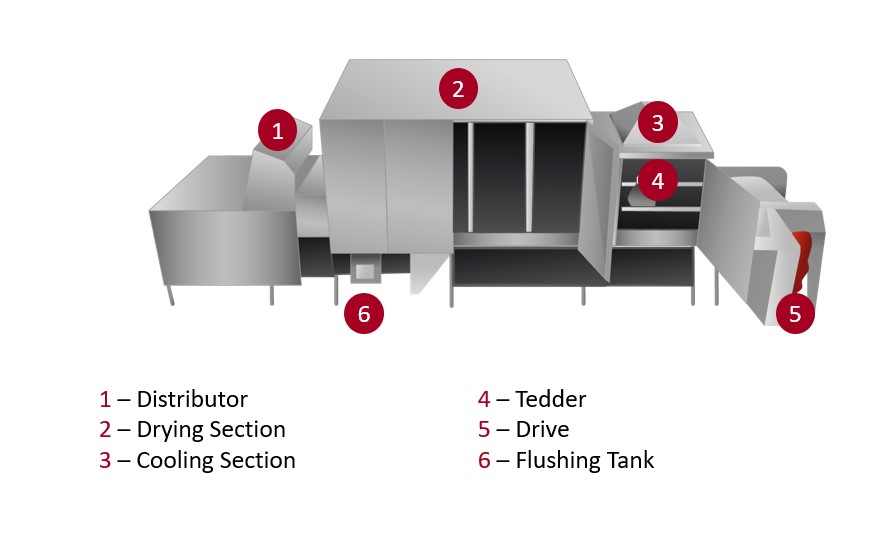

The installation may also include cooling zones of the material. Belt dryers are equipped with various auxiliary equipment - feeders, dispensers, cleaning devices, etc.

The belt dryer consists of a perforated conveyor belt, with which the material to be dried moves through modular drying chambers in which the product contacts the drying gas.

The drying gas may be directed in an ascending, descending or combined manner to create the best conditions for homogeneous processing. The belt speed can be automatically adjusted, which is especially important for products requiring precise processing times.

The installation may also include cooling zones for the material. Belt dryers are equipped with various auxiliary equipment-feeders, distributors, cleaning devices, etc.