Membrane filter presses

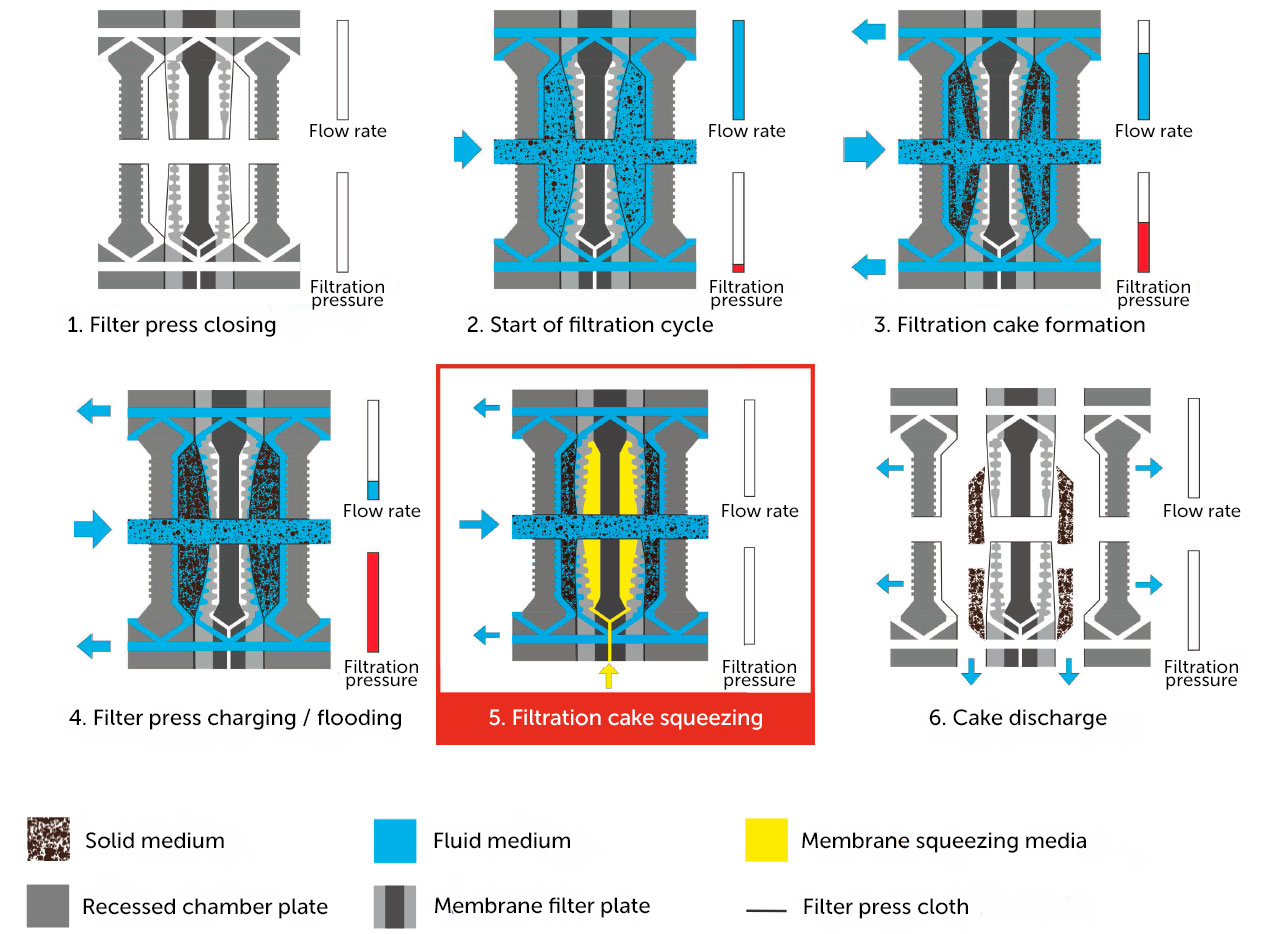

Modern membrane filter presses reduce the filtration cycle, to produce a highly efficient washing and drying the precipitate, without unloading it from the filter, to achieve a low moisture content of sludge. The process of filtration in the membrane filter press is similar to chamber. But the fundamental difference is the fact that when filling the chambers with sediment it is not unloaded immediately, and further is pressed under the action of fluid supplied under the membrane. The possibility of squeezing appears due to the membrane plates. The use of membranes for the mechanical squeezing of sediment can significantly reduce the time of one cycle and enhance the daily performance of the filter press.

Video review

Questionnaire

download

Advantages:

Low final humidity level of squeezing

Highly effective cake washing and/or drying

Full automation of the filtration process

Filtration cycle time cutting

Scope of application:

Non-ferrous metal industry

Mining

Sugar

Chemical industry

Municipal and industrial wastewater treatment

Energy production

Pharmaceuticals industry

Pulp and paper industry

And others

Technical specification: