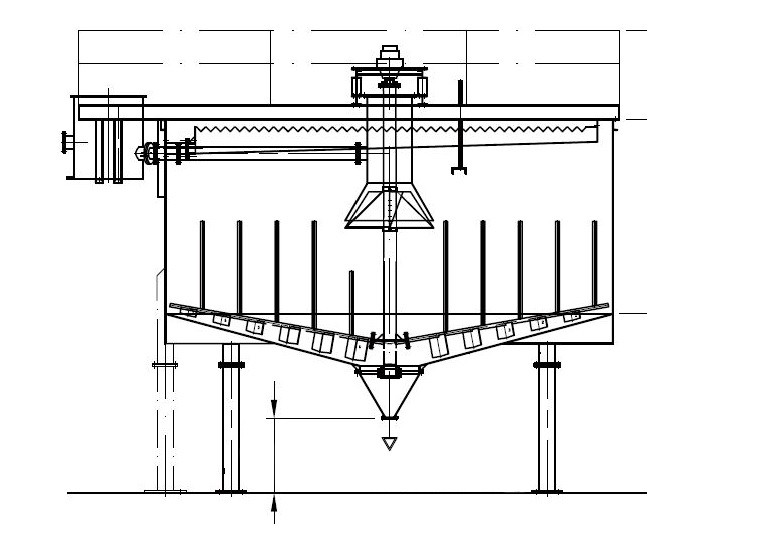

Thickener-clarifier Aka-Set

Radial thickeners with Central drive AKA-SET is for thickening and desliming pulps and slurries, clarification of recycled water and solutions on the mining and processing factories, metallurgical, chemical and other industries.

Thanks to the application of the process of thickening, there is an increase in concentration, i.e., increasing the amount of solids in a certain volume of pulp, which allows you to adjust the pulp density in accordance with subsequent technological operations. The condensing process precedes the process of pressure filtration, allows to increase the efficiency and productivity of processing.

The pulp concentration becomes possible as a result of the deposition of the contained solid particles under the action of the attached mass forces, usually gravitational or centrifugal.

In General, the process of thickening the thickener in compliance with the specified modes of operation the pulp is distributed into several zones according to the depth of thickener. In the upper area of the thickener contains the clarified liquid in the middle area of the pulp with the initial density and at the bottom area of compaction or consolidation. As a result, the fluid pressure upstream layers.

Questionnaire

download

Advantages:

Intensive withdrawal of clarified liquid with minimal evaporation loss due to the reduced radial dimensions

Fully automated dispensing station will optimized reagent consumption

The ability to quickly respond and adapt when changes in operation modes

High performance

Scope of application:

Enrichment of ores, minerals and mineral raw materials

Products of chemical production

Alumina

Coproducts / by-products

Water treatment

High degree of automation of the thickener AKA-SET ensures process stability.

Radial thickener AKA-SET is equipped with a system of LSU with the opportunity for local and remote control. Sensors control the density of the thickened product, clarified the level of the layer is synchronized with the control system for preparation and dosing of flocculant, the discharge system of thickener.

The thickeners have a wide range of sizes, with a diameter of 2.8 m to 18 m

Standard sizes

* Since the A80 type, possible version with the organization of the unsupported system flat bottomed on a concrete base

Why you should choose us

Laboratory and pilot plant testing

High-strength construction

Better suited for work with aggressive media

High efficiency thickening