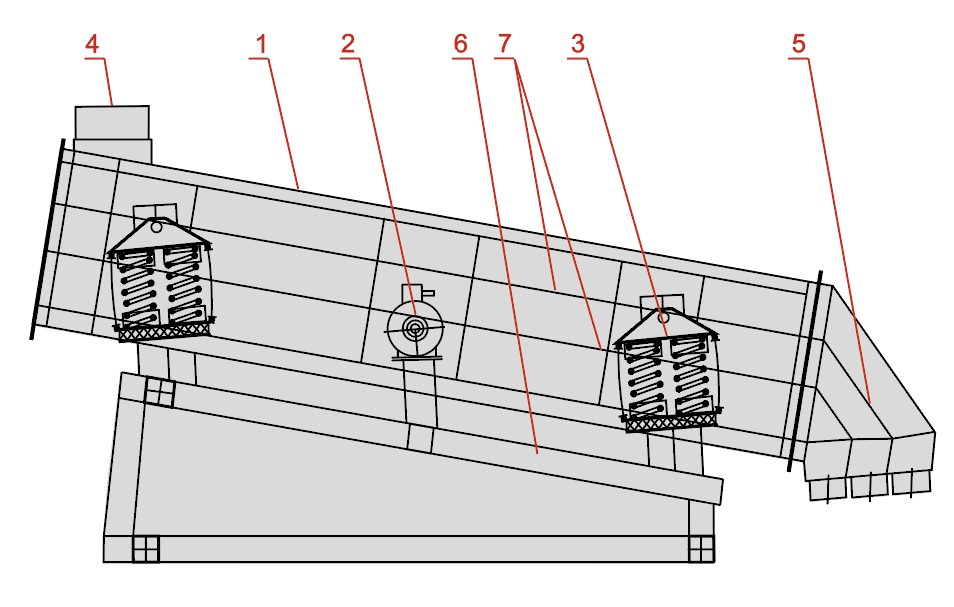

Vibrating screens

Screening machines (screens) are manufactured in both open and closed versions. Closed systems are specially used in connection with extremely dusty, colored or toxic products or in connection with the requirement of a high degree of hygiene.

In the manufacture of screens, materials selected for each specific product are used. Thus, the screens of the screens are made either from stainless steel sheet or from carbon steel sheet with anti-corrosion paint coating. A special wear resistant coating can be provided for highly abrasive materials.

The choice of screening frames is carried out depending on the requirements of the Customer and the characteristics of the process:

- polyurethane sieves

- sieves with perforated plates

- wicker sieves (steel wire mesh)

In the manufacture of screens, materials selected for each specific product are used. Thus, the screens of the screens are made either from stainless steel sheet or from carbon steel sheet with anti-corrosion paint coating. A special wear resistant coating can be provided for highly abrasive materials.

The choice of screening frames is carried out depending on the requirements of the Customer and the characteristics of the process:

- polyurethane sieves

- sieves with perforated plates

- wicker sieves (steel wire mesh)

Questionnaire

download

Advantages:

Simplicity of design

High maintainability

Significantly lower construction height

Lighter and more economical design

Low energy consumption

Non-stop working

Principle of operation:

The sieves in such a screen are either suspended or mounted on hinged mechanisms. Equipped with two counter-rotating vibration motors.

This dual motor configuration causes the screen frame to vibrate in a linear or rectilinear motion perpendicular to the plane of the motors.

For self-cleaning of screens, horizontal screens can be equipped with an additional deck with polyurethane or rubber balls.