Bucket elevator with EVN rubber conveyor belt

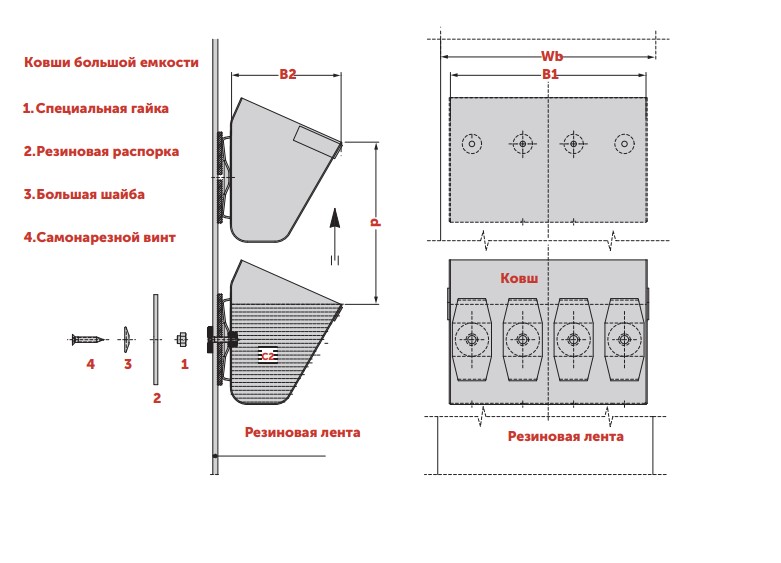

Bucket dimensions (liters), pitch (distance between the centers of the bucket) and lift speed determine the volumetric capacity or lifting capacity of the elevator (in cubic meters per hour).

The shape of the bucket sides affects the maximum speed that can be achieved in a peripheral unloader with any given upper drum diameter to avoid excessive recirculation of material falling into the bottom of the elevator.

For large machines, speed is limited to a maximum of 1.6 m / s (96 m / min) to increase bucket size, resulting in exceptional flow rates and lower bucket costs with fewer buckets.

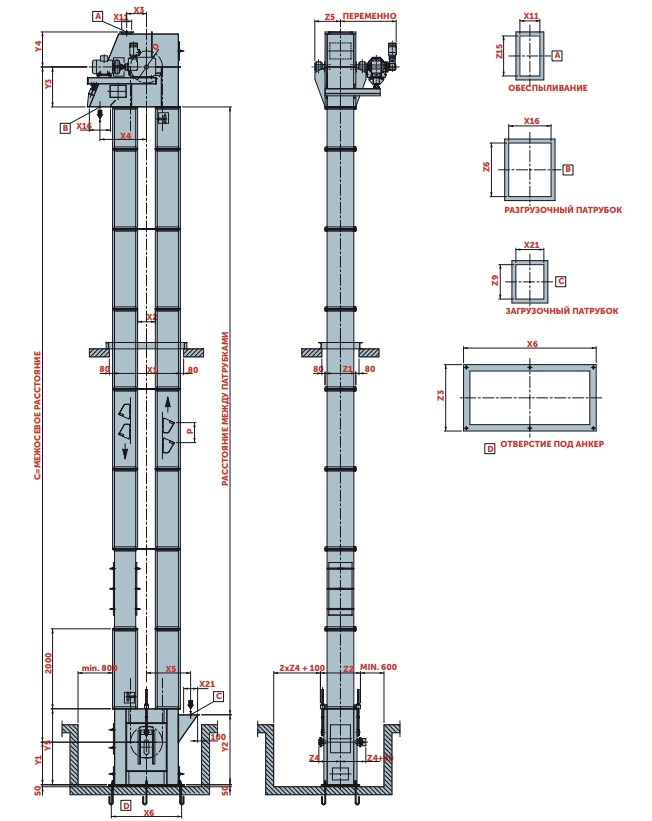

To balance the belt on the move to avoid its displacement from the drums, the tensioning unit of the elevator uses a special parallel tensioning system, consisting of a pair of pantographs with a counterweight.

Questionnaire

download

Scope of application:

Dispersed materials with a temperature not higher than 150 degrees

Continuous buckets, pocket buckets with overlapping edges with drive pin bushings

Drive wheels with replaceable teeth

Continuous chains made of high quality alloy steel

Return wheels with hub and smooth rings

Bucket drive pin, one end of which connects to chains

Material discharge chute under the drive station in the center

Standard tensioning system with contrasting springs, a pair of threaded rods and adjusting nuts

Technical specification:

Allowable material granulometry (mm): 0 - 10

Recommended speed (m / s): 0.90 - 1.60

Allowed center distance (m): 125